CHAPTER |

2 |

Supplier Management

Every one of us might be wondering why companies have to spend a lot of resources, including time, money, and manpower, in supplier management activities such as supplier qualification, supplier performance evaluation, supplier development, and phaseout decisions. There's only one answer to this question, which follows:

Supplier management is less costly than the risk of project failure. If suppliers are not able to deliver what they were contracted for, then contracting organizations lose a lot of money implementing risk purchase, and disaster comes as a project loss.

2.1 Definitions

The following terms will help in understanding complete supplier management activities:

- Supplier

- Supplier Qualification

- Supplier Evaluation

- Supplier Development

- Supplier Phaseout

2.2 Supplier Management Life Cycle

Figure 2.1 depicts the complete life cycle of supplier management, which starts from supplier identification. Once the supplier is selected, they will be qualified and subsequently evaluated during the complete life cycle phases of the project, which are, in general, classified as pre-award, execution, and warranty phase (closing). Once the supplier has been evaluated for all the phases of the project life cycle, they can be classified as the preferred supplier, or categorized based on the organization's methodology of classifying suppliers.

Also clear from the life cycle of supplier management (Figure 2.1), is that once the supplier has been classified, then some of the suppliers may be selected as a non-useful supplier for the organization's future project or business.

We use the word non-useful, as this may be based on bad experiences with the supplier, or may be because of the organization's decision not to take specific projects in the future.

To understand this, let's review an example:

Suppose Organization A is involved in building nuclear power plants and has decided to come out of this business for internal reasons, such as loss in previous projects, or external factors like government regulations. Obviously, Organization A would not request the same set of suppliers in the future, were this organization to begin executing, for example, information technology projects instead.

Based on the supplier's successful evaluation results, the organization may decide to develop a particular supplier for future projects and may decide to support the supplier by suggesting any modifications that may be in the production line—or by suggesting more efficient ways to produce the end product with lesser costs. This is an area that may be said to be part of continuous improvement in customer-supplier relationships.

2.2.1 Supplier Selection and Qualification

The supplier selection process is very important prior to making any purchase decision; certainly, you don't want to send out a request for proposal to the whole world. There would be obvious additional costs, time, and effort required to evaluate the offers received from the suppliers, as today's world is competitive and demands that “just the right supplier” be considered, instead of considering everyone as an approved supplier.

We, as a buying organization, should be clear about whom we want to consider for our requirements. While selecting the supplier, the organization may also decide the criteria for supplier evaluations up front, and with concerned departments like engineering, quality assurance and quality control, project procurement, and project management. Supplier qualification is very important to perform and advance, along with supplier selection, as it would lead to less time getting approval from management, the end customer, or the project owner—and later, nobody will question the purchase proposal prepared by the purchase department.

Sometimes the end customer would like to be involved in the process of selecting the vendor for their project. The end customer providing the list of approved suppliers to the contracting organization can achieve this, or the client may decide to take on the decision during the order award if the awarded supplier is different from the approved supplier list for the project. The buying organization must look into the approved supplier list, if provided, to avoid supplier acceptance discussions later with the end client. By providing an approved supplier list for the project, the client is not promoting any particular supplier, but is trying to use this supplier list as a filter to avoid the contracting organization supplying it with inferior materials or products.

Supplier evaluation criteria are based on two factors: lessons learned from past projects and future forecasting for the supplier. Therefore, criteria may be decided based on earlier projects, including claims made by the supplier during the execution of past projects; any costs incurred on behalf of the supplier because of their own failure to execute the work, the risk purchase, or purchase on behalf of the supplier; any in delivering the material by the supplier at the desired location (i.e., a logistics failure); any cost for the perceived risk in going with the particular supplier; and any additional expediting costs if we select a particular supplier. In other words, evaluation criteria will help in reducing the evaluation time and also provide the complete picture while selecting one supplier over another. Supplier selection is part of supplier qualification, and once the supplier is qualified, then the criteria for supplier evaluation can be decided. Therefore, the organization may have both of the above (supplier selection and supplier evaluation) as different processes, or they can be done simultaneously.

If we do not visit the supplier's works while qualifying them, we would never know the kind of risk-prone areas that could have the potential for compliance and delivery delays.

2.2.2 Supplier Evaluation

Once the supplier is selected and has been considered for outsourcing, along with some of the work or work packages for a specific project, then the supplier needs to be continuously evaluated for conforming to the requirements, and the evaluation should be used to compare the supplier performance against the project-specific requirements, including engineering, procurement, logistics, and quality. Systematic supplier evaluation, as feedback on the supplier's performance, forms the basis for efficient supplier development for future projects and also helps to improve the supplier's relationship with the customer and the supplier's performance. Supplier evaluation results will become the input to the supplier development and phasing out the nonperforming suppliers for future business.

An argument for evaluating supplier performance needs to be made. After all, a lot of resources, including time, have already been spent on the supplier evaluation process.

When I started my career as a buyer, I was of the opinion that it is important to have a good supplier. Everybody needs the best people doing the job, irrespective of the job requirements. Ask engineering colleagues: They only want to evaluate the supplier so that they can report the supplier behavior and performance during the project, and in the future, will know who the good supplier is and who best supplier is. However, from the engineering point of view, the preference is to have the suppliers who follow the instructions of the engineering department and provide support beyond the contract if required. The point is that everybody uses their own yardstick to measure supplier performance. It is better to integrate all the concerned people and let them evaluate the supplier performance; this may include procurement, logistics, engineering, quality, and so on.

2.2.3 Supplier Classification

Once the supplier evaluation is complete, you have the results of evaluations, and you know which supplier has performed as per your expectations and which has failed to meet the requirements. Now you can classify them as poor, average, good, and excellent—or whatever category you want to assign.

There will likely be a supplier who you don't want to consider for future business, and there can be some who you want to further improve. There may be another set of suppliers who have excellent performance.

2.2.4 Supplier Phaseout

The supplier phaseout decision is generally made by the customer based on supplier evaluation results and internal business management decisions. The phasing out decision should not be compared with blacklisting the supplier, as phaseout may happen because the closure of a particular sector of the organization, so the organization is simply not in need of the supplier in the future.

This decision is generally a strategic call and it should be communicated to the supplier even if an organization decides to phase out a supplier because of bad performance. It is not always a good option to phase out a supplier, especially for a patented item or a supplier with the monopoly in the market for a particular item.

2.2.5 Supplier Development

Every organization would like to further develop the suppliers who are top performers and have helped the customer's organization in meeting their goals. Supplier development comes with an increase in spending to award more work to a particular supplier, for local as well as global projects. Supplier development is required, since every organization needs quality suppliers who will be further used in tendering, costing, and estimation for future projects. Initially, supplier development has to be on a trial basis if it is based on increased area of work, such as using the supplier for new work for which they have not yet been evaluated.

2.3 Cost of Quality

Cost of quality is important to understand in getting the answers to the question: Why perform supplier management activities?

Cost of quality includes all costs incurred over the life of the product by investing for prevention of non-conformance costs.

Therefore, cost of quality can be defined as every sum that is spent to meet quality requirements, including prevention costs, appraisal costs, and cost of non-conformance (if any).

Therefore:

Cost of Quality = Prevention Costs + Appraisal Costs + Non-Conformance Costs

2.3.1 Cost of Conformance

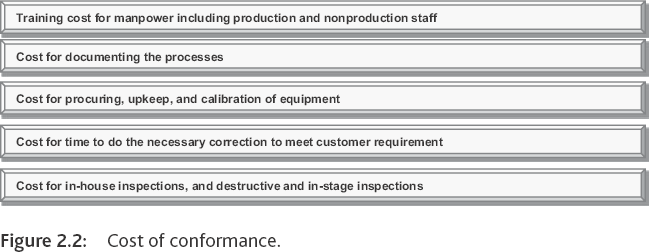

Cost of conformance can be understood as the cost to avoid failures in order to meet customer requirements. This can include various costs, as detailed in Figure 2.2, like the cost for training the production staff, documentation, equipment, and timely calibrations as well as destructive testing of equipment. These costs are incurred by the supplier to comply with requirements, and are lower as compared to costs of non-conformance (see Figure 2.3).

The cost of conformance comprises two types of costs, defined as follows:

- Prevention costs

These costs involve employee training, documenting processes, and procurement of equipment for manufacturing what is required.

- Appraisal costs

These costs involve inspection, destructive testing, and so forth.

2.3.2. Cost of Non-Conformance

Costs of non-conformance are the costs required because of an organization's failure to comply with project requirements.

- Internal failure costs

These are costs that are found by the manufacturer and are incurred because of reworking to comply with customer requirements and/or are due to the complete scrapping of the products under manufacturing. If you are an experienced buyer, you may have heard from the supplier that delivery is getting delayed because of a quality issue at the supplier's end.

- External failure costs

These costs appear because of defects found by the customer; and normally, such costs are very high. These can be liabilities, warranty costs, and so on.

Therefore, the cost of non-conformance can be due to following factors, as detailed in Figure 2.3.