The Future in Nuclear Power

Perceptions of nuclear power tend to be dominated by concerns on safety and waste management, and the key to understanding how these can be handled with security and sustainability is a fundamental understanding of nuclear processes and materials. This chapter traverses the chapters from atomic-level nuclear changes, to reactor options, and finally the handling of spent nuclear fuel. A comprehensive understanding leads to comprehensive solutions that are sustainable.

Keywords

Beta particle; neutron; atom; radiation; fission; reactor; isotope

Shortly before World War II the physics research community learned that the uranium-235 isotope would fission when exposed to a beam of neutrons. When a uranium nucleus split a huge surge of energy and two or three neutrons were released. The potential use of these data indicated it would be possible to assemble a powerful explosive weapon. All of the research that led to the production of the two nuclear bombs that exploded over Hiroshima and Nagasaki Japan was labeled “top secret.” This ended World War II with the surrender of Japan.

There were lots of freight shipped during World War II and the German submarines were a plague—sinking a high percentage of the Allied surface vessels. Submarines used diesel electric generators to charge their batteries that allowed them to cruise underwater using stored electric power. A submarine had to come close to the surface so that the diesel engines could “breathe” to charge the batteries. This signaled their location. Admiral Hyman Rickover was assigned the task of “taming” the nuclear fission process to produce energy to charge the submarine batteries while they were under water. This made the Nuclear Navy possible with submarines cruising under water—undetected for 90 of more days.

Civilian contractors building submarines made their living building coal-fired electric power plants. There was a Federal “Atoms for Peace Initiative” that made a perfect fit for using the submarine nuclear power plant as the staring model for civilian nuclear power plants. The secrets for this application were suspended and civilian nuclear power was launched. This chapter presents some details of this effort and includes some proposals pointing to the future of civilian nuclear energy.

Energies of Nuclear Processes

The huge quantities of energy liberated in nuclear power plants come from the nuclei of atoms. In the fission process, relatively stable nuclei are induced into excited states that fission and release energy as they form new smaller stable atom nuclei. The heat produced in the nuclear reactor is converted to work through a heat engine power cycle.

The natural stability of atoms is characterized by their half-life. The half-life of U-238 is 4.5×109 years. If 1 pound of pure U-238 were flying through outer space today, in 4.5 billion years that meteor would have a total mass slightly less than 1 pound—one half pound would be U-238 and the other half would be fission products, mostly lead. Since the earth is about 5 billion years old, the U-238 present on earth today is about half of that present when earth was formed.

While the atomic stability is typically discussed in relative rather than absolute terms, atoms with half-life greater than 4.5 billion years are generally considered stable. Lead (Pb-206) is stable; the change in concentration of a 1-pound lead meteor would be negligible over a 4.5-billion-year period.

The decay of U-238 is a natural process (specifically, an α-decay process1). An unnatural decay of a nucleus, nuclear fission can be induced by collision with a neutron. A nuclear reactor environment is designed to sustain a critical concentration of free neutrons that gives a constant and controlled source of heat from induced fission. U-235 is the isotope that provides most of the energy nuclear reactor. Figure 8.1 illustrates the overall process by which U-235 releases heat through neutron-induced fission.

The energies released from the excited nuclei are not common in nature. However, analogous electron processes are regularly observed. For example, an incandescent light bulb operates on the principle of using electric power to increase the energy of the metal filament (high temperature)—some of this energy produces excited states of the electrons that surround the metal nuclei. These excited electron states emit visible radiation (light) as they return to lower energy, more stable states or ground states.

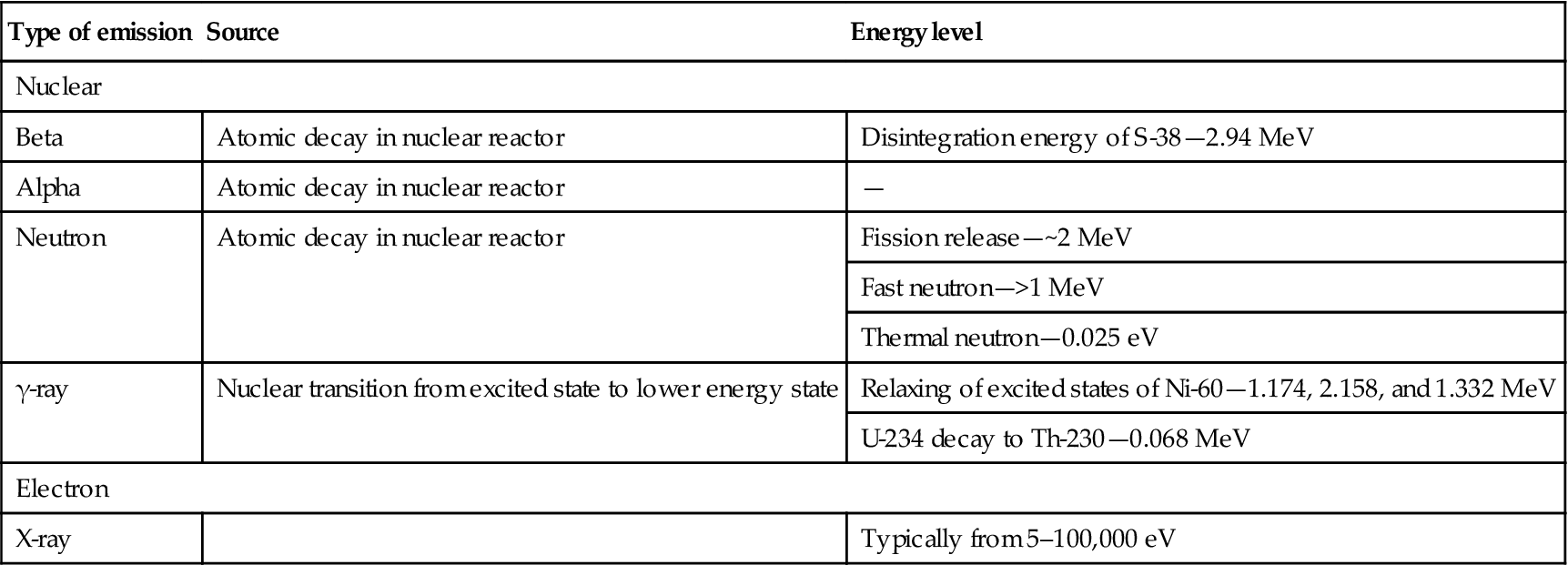

Table 8.1 provides several example emissions that occur when electrons and nuclei go from excited states to ground states (referred to as stable states for nuclei)—electrons and nuclei have multiple excited states and one or two stable/ground states. The energies are reported in electron volts; one electron volt is equivalent to 1.602×10−19 joules or 1.18×10−19 foot pounds.

Table 8.1

Examples of different emissions from nuclei and electrons

| Type of emission | Source | Energy level |

| Nuclear | ||

| Beta | Atomic decay in nuclear reactor | Disintegration energy of S-38—2.94 MeV |

| Alpha | Atomic decay in nuclear reactor | — |

| Neutron | Atomic decay in nuclear reactor | Fission release—~2 MeV |

| Fast neutron—>1 MeV | ||

| Thermal neutron—0.025 eV | ||

| γ-ray | Nuclear transition from excited state to lower energy state | Relaxing of excited states of Ni-60—1.174, 2.158, and 1.332 MeV |

| U-234 decay to Th-230—0.068 MeV | ||

| Electron | ||

| X-ray | Typically from 5–100,000 eV | |

Among the lowest energy emissions from electrons is visible light resulting from electricity flowing through an incandescent light bulb. Among the highest energy emissions are neutrons emitted as part of atomic decay (2,000,000 eV). As illustrated by the comparison of Table 8.2, the energies associated with atomic processes are much larger than electron processes; atomic processes tend to be useful in large power plants while electronic processes tend to have applications in homes and offices.

Table 8.2

Examples of energy levels in electron volts for different processes

| Other processes | |

| U-235 fission to Rb-93+Cs-140 | 200 MeV |

| Ionization | Remove outer electron from lead—7.38 eV |

| Remove inner electron from lead—88,000 eV | |

| Mass defect | Mass defect of Li-7—931.5 MeV |

| Binding energy | Binding energy of Li-7—1784 MeV |

Electron emissions tend to be photonic (light, energetic x-rays); nuclear emissions may be photonic (γ-rays) or have white particle mass (α, β, and neutron) as energy components.

Of the emissions in Table 8.1, only the neutrons can collide and combine with an atom nucleus—often leading to an unstable state of the nucleus. In some physics laboratories atomic accelerators are able to increase the energy of particles that collide to produce excited nuclei or new elements.

If neutron loses enough energy through collisions, it will at sufficiently low energy convert to atomic hydrogen (one proton and one electron). Beta (β) particles become electrons, and alpha (α) particles become helium (He-4). These transitions are summarized in Table 8.3.

Table 8.3

While electronic emissions dissipate, nuclear emissions do not dissipate

| Type of emission | Product of emission |

| Nuclear | |

| Beta | Is newly produced, excited electron |

| Alpha | Is newly produced, excited helium atom nucleus |

| Neutron | Is newly produced, excited atomic hydrogen (but remains a neutron if incorporated into another nucleus) |

The US Department of Energy publication entitled DOE Fundamentals Handbook, Nuclear Physics and Reactor Theory, Volume 1 of 2 [1] provides a detailed summary of key aspects of nuclear physics including the following excerpts (italics) that describe nuclides, nuclear stability, and conventions for reporting the atomic information.

Chart of the Nuclides

A tabulated chart called the Chart of the Nuclides lists the stable and unstable nuclides in addition to pertinent information about each one. Figure 8.2 shows a small portion of a typical chart. This chart plots a box for each individual nuclide, with the number of protons (Z) on the vertical axis and the number of neutrons (N=A–Z) on the horizontal axis.

The completely gray squares indicate stable isotopes. Those in white squares are artificially radioactive, meaning that they are produced by artificial techniques and do not occur naturally. By consulting a complete chart, other types of isotopes can be found, such as naturally occurring radioactive types (but none are found in the region of the chart that is illustrated in Figure 8.2).

Located in the box on the far left of each horizontal row is general information about the element. The box contains the chemical symbol of the element in addition to the average atomic weight of the naturally occurring substance and the average thermal neutron absorption cross section, which will be discussed in a later module. The known isotopes (elements with the same atomic number Z, but different mass number A) of each element are listed to the right.

Information for Stable Nuclides

For the stable isotopes, in addition to the symbol and the atomic mass number, the number percentage of each isotope in the naturally occurring element is listed, as well as the thermal neutron activation cross section and the mass in atomic mass units (amu). A typical block for a stable nuclide from the Chart of the Nuclides is shown in Figure 8.3.

Information for Unstable Nuclides

For unstable isotopes the additional information includes the half-life, the mode of decay (for example, β−, α), the total disintegration energy in MeVTable (million electron volts), and the mass in amu when available. A typical block for an unstable nuclide from the Chart of the Nuclides is shown in Figure 8.4.

Neutron–Proton Ratios

Figure 8.5 shows the distribution of the stable nuclides plotted on the same axes as the Chart of the Nuclides—it provides the skeleton of the complete Chart of Nuclides. As the mass numbers become higher, the ratio of neutrons to protons in the nucleus becomes larger. For helium-4 (2 protons and 2 neutrons) and oxygen-16 (8 protons and 8 neutrons) this ratio is unity. For indium-115 (49 protons and 66 neutrons) the ratio of neutrons to protons has increased to 1.35, and for uranium-238 (92 protons and 146 neutrons) the neutron-to-proton ratio is 1.59.

If a heavy nucleus were to split into two fragments, each fragment would form a nucleus that would have approximately the same neutron-to-proton ratio as the heavy nucleus. This high neutron-to-proton ratio places the fragments below and to the right of the stability curve displayed by Figure 8.5. The instability caused by the excess of neutrons is generally rectified by successive beta emissions, each of which converts a neutron to a proton and moves the nucleus toward a more stable neutron-to-proton ratio.

Careful measurements have shown that the mass of a particular atom is always slightly less than the sum of the masses of the individual neutrons, protons, and electrons of which the atom consists. The difference between the mass of the atom and the sum of the masses of its parts is called the mass defect (Δm).

The loss in mass, or mass defect, is due to the conversion of mass to binding energy when the nucleus is formed. Binding energy is defined as the amount of energy that must be supplied to a nucleus to completely separate its nuclear particles (nucleons). It can also be understood as the amount of energy that would be released if the nucleus was formed from the separate particles. Binding energy is the energy equivalent of the mass defect. Since the mass defect was converted to binding energy (BE) when the nucleus was formed, it is possible to calculate the binding energy using a conversion factor derived by the mass-energy relationship from Einstein’s Theory of Relativity.

Energy Levels of Atoms

The electrons that circle the nucleus move in fairly well defined orbits. Some of these electrons are more tightly bound in the atom than others. For example, only 7.38 eV is required to remove the outermost electron from a lead atom, while 88,000 eV is required to remove the innermost electron. The process of removing an electron from an atom is called ionization, and the energy required to remove the electron is called the ionization energy.

In a neutral atom (number of electrons=Z) it is possible for the electrons to be in a variety of different orbits, each with a different energy level. The state of lowest energy is the one in which the atom is normally found and is called the ground state. When the atom possesses more energy than its ground state energy, it is said to be in an excited state.

An atom cannot stay in the excited state for an indefinite period of time. An excited atom will eventually transition to either a lower-energy excited state, or directly to its ground state, by emitting a discrete bundle of electromagnetic energy called an x-ray. The energy of the x-ray will be equal to the difference between the energy levels of the atom and will typically range from several eV to 100,000 eV in magnitude.

Energy Levels of the Nucleus

The nucleons in the nucleus of an atom, like the electrons that circle the nucleus, exist in shells that correspond to energy states. The energy shells of the nucleus are less defined and less understood than those of the electrons. There is a state of lowest energy (the ground state) and discrete possible excited states for a nucleus. Where the discrete energy states for the electrons of an atom are measured in eV or keV, the (k=1000) energy levels of the nucleus are considerably greater and typically measured in MeV (M=1,000,000).

A nucleus that is in the excited state will not remain at that energy level for an indefinite period. Like the electrons in an excited atom, the nucleons in an excited nucleus will transition towards their lowest energy configuration and in doing so emit a discrete bundle of electromagnetic radiation called a gamma ray (γ-ray). The only differences between x-rays and γ-rays are their energy levels and whether they are emitted from the electron shell or from the nucleus. The ground state and the excited states of a nucleus can be depicted in a nuclear energy-level diagram. The nuclear energy-level diagram consists of a stack of horizontal bars, one bar for each of the excited states of the nucleus. The vertical distance between the bar representing an excited state and the bar representing the ground state is proportional to the energy level of the excited state with respect to the ground state. This difference in energy between the ground state and the excited state is called the excitation energy of the excited state. The ground state of a nuclide has zero excitation energy. The bars for the excited states are labeled with their respective energy levels. Figure 8.6 is the energy level diagram for nickel-60.

Stability of Nuclei

As mass numbers become larger, the ratio of neutrons to protons in the nucleus becomes larger for the stable nuclei. Non-stable nuclei may have an excess or deficiency of neutrons and undergo a transformation process known as beta (β) decay. Non-stable nuclei can also undergo a variety of other processes such as alpha (α) or neutron (n) decay. As a result of these decay processes, the final nucleus is in a more stable or more tightly bound configuration.

Natural Radioactivity

In 1896, the French physicist Becquerel discovered that crystals of a uranium salt emitted rays that were similar to x-rays in that they were highly penetrating, could affect a photographic plate, and induced electrical conductivity in gases. Becquerel’s discovery was followed in 1898 by the identification of two other radioactive elements, polonium and radium, by Pierre and Marie Curie.

Heavy elements, such as uranium or thorium, and their unstable decay chain elements emit radiation in their naturally occurring state. Uranium and thorium, present since their creation at the beginning of geological time, have an extremely slow rate of decay. All naturally occurring nuclides with atomic numbers greater than 82 are radioactive. X

Nuclear Decay

Table 8.4 provides examples of different types of nuclear transitions. These transitions can be from a highly unstable nucleus or from a relatively stable nucleus. A highly unstable nucleus has a short half-life (time in which the concentration of that isotope is reduced by 50% due to atomic transition) while stable molecules have long half-lives.

Table 8.4

Example notations of nuclear processes

| Process | Formula | Description [1] |

| Alpha decay | KE is kinetic energy of the α-particle is helium nucleus | |

| Beta decay | Neutron converted to proton | |

| ν represents a neutrino—interacts little with atoms and escapes at speed of light | ||

| Beta decay | Proton converted to neutron through positron formation | |

| Electron capture | Proton is converted to neutron by electron capture |

During and immediately after the burn of a nuclear fuel rod, radiation levels are very high due to the large number of radio nuclides with short half-lives. By definition, these short half-life nuclei rapidly undergo nuclear transitions. For a given nuclei, this process continues in a decay chain until a molecule with a stable or long-half-life nucleus is formed. The following decay of rubidium-91 to zirconium 91 illustrates a decay chain. The numbers under the arrows indicate half-lives in seconds, hours, days, and years.

These decay chains are important when treating fission products. The short-lived products will rapidly decay. If spent fuel is stored for 30 years at the nuclear power plant, this time will reduce the concentration of all nuclides with half-lives less than 3 years to a concentration less than 0.1% of the initial concentration.

Fortunately, the majority of the short-lived isotopes decay to stable nuclides. About 10% of the fission products remains as high-level waste after 30 years of storage—the remainder have decayed to stable nuclides.

Conditions for Successful Nuclear Fission

For nuclides to successfully undergo neutron-induced fission, a number of conditions must be met that are analogous to a chemical reaction. Table 8.5 summarizes and compares the factors that lead to fission with those conditions that promote chemical reactions.

Table 8.5

Factors impacting the rate of nuclear fission versus analogous factors for chemical reaction

| Factor | Nuclide | Chemical reagent |

| Materials must have a propensity to react | A low critical energy that corresponds to classifications as fissile or fissionable | A low activation energy |

| Materials must have ability to go to lower energy state | Products must have a higher binding energy | Products must have a lower Gibbs free energy |

| Degree of molecular excitement should be optimal | The energy of the neutron must be correct—high (fast) or low (thermal) energy level may be optimal | Temperature must be high enough to react but low enough to stabilize the products |

| Events must be concentrated rather than disperse | Concentrations of reacting materials (e.g., U-235) must be high enough to sustain reaction but not so high to run away (explode) | High concentrations are needed for reasonable reactor size, or a solvent must be used to avoid run away |

These topics are discussed in the following four sections.

(a) Uranium and Other Fertile Materials

A nuclear reactor is designed to provide a flux of neutrons with the right energy to provide a constant, steady rate of nuclear fission. Each U-235 yields about 200 MeV per atom of uranium that undergoes fission.

U-235 is referred to as a fissile material because U-235 will absorb a neutron with very low kinetic energy (referred to as thermal neutrons) and this produces fission. Table 8.6 summarizes the three types of materials that are of interest in nuclear fission fuels. Fissile atoms undergo fission because a neutron of low kinetic energy can induce fission.

Table 8.6

Definitions and examples of nuclear fission fuels

| Material category | Definition | Examples |

| Fissile | Nuclides for which fission is possible with neutrons of any energy level | U-235, U-233, and Pu-239 |

| Fissionable | Nuclides for which fission is possible with neutron collision | U-235, U-233, Pu-239 |

| Fertile | Materials that can absorb a neutron and become fissile materials | U-238 and Th-232 |

When a neutron combines with a stable nucleus, a binding energy (BE) corresponding to that neutron addition is released. When that BE is greater than a critical energy (specific to the nuclide before addition of the neutron), the nuclide can undergo fission. Table 8.7 provides the binding energies (MeV/nucleon) and critical energies of the five fissile and fissionable materials. Th-232 and U-238 are fissionable, but not fissile because it takes higher energy neutrons to bring sufficient kinetic energy so that the sum of kinetic and binding energies exceeds the “critical energy” producing fission.

Table 8.7

Critical energy versus energy released with absorption of additional neutron [1]

| Target nucleus | Critical energy Ecrit | Binding energy of last neutron BEn | BEn − Ecrit |

| Th-232 | 7.5 MeV | 5.4 MeV | −2.1 MeV |

| U-238 | 7.0 MeV | 5.5 MeV | −1.5 MeV |

| U-235 | 6.5 MeV | 6.8 MeV | ±0.3 MeV |

| U-233 | 6.0 MeV | 7.0 MeV | +1.0 MeV |

| Pu-239 | 5.0 MeV | 6.6 MeV | +1.6 MeV |

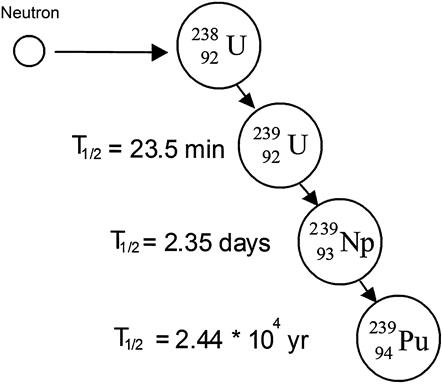

When U-238 or Th-232 absorb neutrons and fission does not occur, they can undergo the decay chain summarized in Figure 8.7 resulting in the formation of U-233 and Pu-239. U-238 and Th-232 are referred to as fertile materials because absorption of a neutron can produce a fissile material. Because of these nuclear processes, it is possible for a nuclear reactor to produce more fuel than is consumed—reactors designed to do this are called breeder reactors. In light water converter reactors (also referred to as burner reactors), that consume more fuel than is produced, about one-third of the energy produced is a result of Pu-239 production with subsequent Pu-239 fission. At the end of the nuclear fuel burn in a light water reactor about 0.9% Pu-239 remains in the fuel. The new fuel initially contained 3.4% U-235 (0% Pu-239).

The decay chains in Figure 8.7 (absorption without fission) are broadly referred to as transmutation processes. Transmutation is important for converting fertile fuel to fissile fuel. The susceptibility of materials to transmutation is covered in the next section under the topic of absorption cross section.

Transmutation is important for creating fissile materials and for converting problem radioactive wastes into more benign materials. Not all nuclides in nuclear waste present the same degree of waste handling problems. For example, nuclides with short half-lives (less than about 5 years) can be stored until the radioactive decay reaches benign levels. Wastes with very long half-lives tend to be less hazardous than the uranium mined to create the nuclear fuel. However, wastes with intermediate half-lives are more hazardous than natural ores. They take too long to decay in 30–60 years used for temporary storage. Transmutation can transmute some of these waste materials into new nuclides that decay quickly or that are stable.

(b) Binding Energy Constraints

Available technology limits sustainable fission power to fissionable materials originating from natural uranium and thorium. For fission to occur, the nuclei produced from the nuclear transformation must have a higher BE than the nuclei undergoing fission (see definition of BE). BE is defined so that higher binding energies represent more permanent nuclei. The most stable nuclei, like iron, have the highest binding energies.

The BE trends in Figure 8.8 illustrate that those nuclei with atomic weights greater than about 60 can undergo fission to produce more tightly bound nuclei. Nuclei with atomic weights less than about 60 can undergo fusion to produce more tightly bound nuclei.

The total energy release from the fission of U-235 is about 200 MeV. About 187 MeV of the energy is immediately released in the form of kinetic energy of the fission fragments, kinetic energy of the fission neutrons, and γ–rays. The excited product nuclei will release the remaining 13 MeV in the form of kinetic energy of delay beta particles and decay γ–rays. Table 8.8 reports average quantities of instantaneous and delayed energy release from U-235 fission by a thermal neutron. Of these emissions, the 10 MeV of energy from the neutrinos escape the reactor system.

Table 8.8

Instantaneous and delayed energy from fission [1]

| Instantaneous | |

| Kinetic energy of fission products | 167 MeV |

| Energy of fission neutrons | 5 MeV |

| Instantaneous γ-ray energy | 5 MeV |

| Capture γ-ray energy | 10 MeV |

| Total | 187 MeV |

| Delayed | |

| β-Particles form fission products | 7 MeV |

| γ-rays from fission products | 6 MeV |

| Neutrinos | 10 MeV |

| Total | 23 MeV |

(c) Nuclear Cross Sections

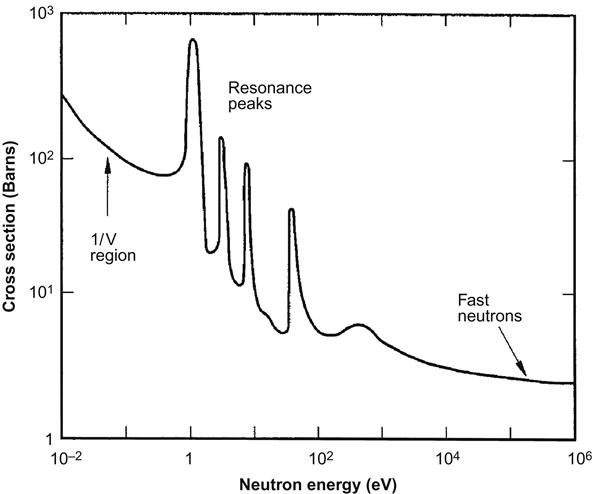

Nuclear cross sections are tabulated for atoms and characterize the susceptibility of the nuclide to interact with a neutron. Different representative cross sections are reported for different types of interaction. While fissile, fissionable, and fertile classifications indicate what happens if a neutron is absorbed by a nuclide, the cross section indicates the size of the target for neutron capture.

The cross sections are dependent on the energy of the neutron and the properties of the nuclide. These microscopic cross sections may be viewed as the area available for a neutron to hit to induce reaction. A larger cross section provides an increased probability for reaction.

Table 8.9 provides example nuclear cross sections for U-235 and U-238. Cross sections (reported in barns, 1 barn=10−24 cm2) for both fission and capture are provided. The thermal neutrons (<1 eV) typically have cross section 20–30 times larger than fast neutrons (1–2 MeV). It is this large cross section for U-235 and thermal neutrons that made it the fuel of choice for commercial nuclear reactors.

Table 8.9

Example cross section areas [2]

| Nuclide | Kinetic energy of neutron (eV) | Fission cross section (barns) | Capture cross section (barns) |

| U-235 | 0.5 | 50 | 7 |

| U-235 | 1,000,000 | 2 | 0.15 |

| U-238 | 0.5 | 0.6 | N/A |

| U-238 | 1,000,000 | 0.1 | 0.02 |

Fission and capture cross sections are two of the four cross sections that dominate nuclear reactor behavior. Table 8.10 illustrates these and includes elastic and inelastic cross sections.

Table 8.10

Illustration of prominent cross sections in nuclear reactors

| Process | Description [1] |

| Fission |  |

| Transmutation |  |

| Scattering (elastic) |  |

| Scattering (inelastic) |  |

The fission cross sections for U-235 is about 50 barns for the thermal neutron versus 2 barns for the fast neutron. For U-235 (fissile), the fission cross section is greater than the capture cross section, fission will occur more often than capture.

Fertile nuclides like U-238 have critical fission cross sections below a neutron energy level. The fission cross section for U-238 is equal to the capture cross section at 1.3 MeV. Higher energy neutrons will tend to cause fission while lower energy neutrons will tend to cause transmutation, the pathway to forming plutonium.

Fission, capture, scatter, and total cross sections are a few of the different types of cross sections that are characterized. Figure 8.9 shows a typical plot of total nuclear cross section area versus the energy level of the neutron. The complex nature of the free neutron interaction with nuclei goes beyond the scope of this text with much yet to be learned. Key points have been presented; especially important is the distinction between thermal neutrons (<1 eV) and fast neutrons (typically >1 MeV). The thermal neutron is key in propagating reactions in the Generation II nuclear reactors including current commercial light water reactors. For fast-spectrum reactors (the Generation IV designs) fast neutrons are key to the performance. Fast neutrons can directly induce fission in U-238 and can fission actinides.

Actinides are nuclides with atomic numbers between 89 and 104 (at an atomic number of 92, uranium is an actinide). Actinides such as plutonium (Pu), neptunium (Np), americium (Am), and curium (Cm) are formed in nuclear reactors (see Table 8.11). Once formed, they can continue absorbing thermal neutrons, eventually reducing the number of neutrons available to promote fission. Fast neutrons tend to produce fission. So, fast neutrons cause actinides to release fission energy (rather than inhibit other fission processes).

Table 8.11

Transuranic elements of primary interest to AFCI program including uranium as reference

|

| Why does transuranic matter? [3] • Transuranic elements affect repository performance by dominating long-term heat load and long-term radiotoxicity. • Transuranic elements and enriched uranium are the only materials of concern for proliferation. • Transuranic elements can be destroyed while producing extra energy if recycled in (fast spectrum) nuclear reactors. |

Fast-spectrum reactors are important for sustainable nuclear power. Fast-spectrum reactors eliminate the need to separate the actinides when reprocessing nuclear fuel. This reduces the cost and promotes sustainable economics. Using all the actinides as fuel removes them from the waste stream and eliminates the long-term storage problem.

(d) Concentrated Events

Fissile materials U-235 and Pu-239, meet the constraints of fission and, release energy as they form smaller, more stable nuclei. The chain reaction is maintained by the neutron flux. The final components of the controlled release of the nuclear energy are the initiation of the neutron flux and maintaining the neutron flux. The neutron flux is the number of neutrons passing through an area of 1 sq. cm per second. Since the neutrons tend to be moving through solids (stopped or scattered only by the dense nuclei of the atoms in the solid), the energy of the neutrons decreases (they slow down) as they travel through the reactor core.

A discussion of materials for initiating the neutron flux is beyond the scope of this text. There are such materials that are used to start the reactor by initiating fission.

Sustaining the neutron flux is the most important criteria in nuclear reactor design. The neutron flux is depleted by neutron capture and by scattering out of the reactor core volume. The neutron poisons (boron as boric acid in the reactor cooling water) are used to maintain the neutron flux for constant energy production.

In a controlled reactor environment, the flow of neutrons (the neutron flux) achieves a steady state consistent with the desired heat (energy) release. This is achieved with the right concentration of U-235 or Pu-239 present—achieved by concentrating them in the fuel rods and proper spacing of the fuel rods. The right fuel rod concentration is typically between 2.6% and 4.0% U-235 in a light water reactor. Some of the proposed Generation IV designs may use concentrations up to 20%. The spacing of the fuel rods in the reactor and the fissile isotope concentration in the fuel provide the controlled release of energy. Since the medium (water) between the fuel rods changes the kinetic energy of the neutrons, it is important to match the medium with fuel composition and spacing.

Light water reactors are designed for controlled delivery of thermal neutrons (<1 eV) to the fuel rods. Liquid water (not water vapor) between the fuel rods provides an average of 12 scattering collisions with water to produce the thermal neutrons that will successfully fission another U-235 nucleus.

If water is absent, the energy level of the neutrons is too high, the lower nuclear cross section leads to fewer successful absorption processes—and to the escape of the neutrons from the reactor core. In light water reactors, this happens if water vapor is present between the fuel rods and this will lead to a “passive” shutdown of the reactor. The flow of cooling water must be maintained when the reactor is shut down to remove the decay heat from the fission products in the fuel that continue spontaneous decay and energy release.

In fast flux Generation IV reactors, the reactor configurations and fuel isotope concentrations are such that the system relies on the collisions of fast neutrons to propagate the nuclear fission process. The higher energy neutrons allow direct use of fissionable materials (both fissile and fertile isotopes) to propagate the nuclear fission process.

The neutron absorption by U-238 leads to formation of all the transuranic elements formed in reactor fuel since each element formed is promoted by absorbing a neutron. In a fast flux reactor these actinide nuclei accept fast neutrons and they undergo fission. In thermal flux reactors, these higher actinides accumulate and contribute to the radioactive “waste” problem. The excitation and fission (energy release) of all actinides in Generation IV reactors represent an important step toward sustainable nuclear energy because this process reduces waste, makes fuel recycling easier. It allows total use of the uranium fuel. This includes the vast stockpiles of depleted uranium left from producing military highly enriched U-235 and the low enriched domestic fuel for domestic electric power plants.

Transmutation

For every 100 kg of fuel introduced into a light water reactor, about 3.4 kg of fission products are produced at refueling. Of these fission products, about 0.4 kg remain as high level radioactive waste after about 30 years of storage at the nuclear power plant. This 0.4 kg can be placed is a repository as “high-level” waste for about 1000 years to become stable, or it could be transmuted. The transmutation of I-125 (see insert) is considered viable with existing methods. Iodine is about 0.1 kg of the high-level waste in a metric ton of spent fuel. Other techniques could be developed for the other 0.3 kg. Following is from a Department of Energy (DOE) Report to Congress [4]. This provides a summary of transmutation possibilities.

While plutonium-based fuels have been manufactured on a commercial basis, almost no work has been done on making or irradiating fuels that contain neptunium, americium, or curium.

Transmutation fuels that can significantly destroy the higher actinides should be capable of very high burnups to minimize the number of recycles required to reduce material losses during separations and fabrication steps. They should be easily fabricated in hot cells or some other remote environment due to the high radiation levels from the minor actinides. If these advanced fuels are to be useful candidates for potential deployment with Generation IV systems, research, development, and testing would be needed beyond Phase II. Advanced Fuel Cycle Initiative (AFCI), an internationally supported program, Series Two would apply considerable effort to evaluating the various fuel types that could serve as an optimum fuel for fast spectrum reactor or accelerator-driven transmutation systems.

The determination of the optimum fuel form for transmutation—a fuel that may be easily fabricated using remote handling technologies contributes to the safe operation of the reactor and results in a final waste form acceptable for a repository to be designated—is a major research objective of the program.

Oxide, nitride, metallic, dispersion, ceramic, and coated particle fuel forms are currently under investigation. Fabrication of several test fuel specimens of these fuel forms containing plutonium mixed with minor actinides is underway. The Department (DOE) plans to irradiate these fuels in the Advanced Test Reactor (ATR) in Idaho with a more ambitious follow-on irradiation program to be carried out in France by other European partners. A consortium of institutions is planning the construction of an experimental assembly containing minor actinide fuels that would come from several countries; this assembly would be irradiated in a French fast spectrum reactor (PHENIX).

Successful testing in the ATR and initiation of the French PHENIX tests during Phase II would permit DOE to select the most promising path forward for AFCI Series Two transmutation fuels including planning for potential Phase III scaled-up fast spectrum irradiations in foreign facilities.

Fast spectrum systems can be either fast reactors (which employ critical reactor cores that operate 12–18 months between refueling cycles) or accelerator-driven systems that employ reactor cores that are subcritical by nature (i.e., they need a constant source of neutrons to maintain a normal operating state). The external source of neutrons is produced by an accelerator and a target system. Both systems employ fast neutrons; however, the accelerator system has the advantage that it can transmute all radioactive elements without producing any plutonium in the process.

Accelerator systems are more expensive than fast reactors, and require significantly more research and development, although the fuel technology is basically the same.

While the Department, based on the systems analysis carried out in Phase I of this research, does not expect accelerator transmutation systems to be used as the primary transmuter of the long-lived toxic materials present in spent fuel, they may have an important role assuring the very low levels of toxicity that serve as the technology goals of this activity. The relatively high construction and operating costs of accelerator-based systems make them unsatisfactory for widespread application as commercial-scale transmuters. Fast reactor systems, however, may prove sufficiently economic to justify their eventual deployment—this is a key element of evaluation in the multinational Generation IV Nuclear Energy Systems Initiative. (The Generation IV International Forum: Update, October 2002 is included as Appendix B.)

Accelerator-Driven Systems Physics and Materials Research and Development

Many countries are considering accelerator-driven systems (ADSs) as a viable approach to transmutation because these systems may be capable of destroying long-lived radioactive isotopes of all types without making plutonium. An ADS consists of an accelerator that produces high-energy protons that strike a heavy metal target to produce high-energy (fast) neutrons through a spallation process to drive a subcritical reactor assembly.

Accelerator-driven transmutation (see insert) has been an important part of nuclear physics research for decades.

Nuclear Fusion

It is difficult to predict what energy options will be available in 30, 100, or 200 years. Nuclear fusion is the primary source of energy in the universe and may be an option that can be made available. The following is a summary of nuclear fusion energy as prepared by the Congressional Research Service (CRS) of the Library of Congress [5].

The potential benefits of controlled fusion are great. Successful development of a fusion power plant, however, is proving to be a very difficult scientific and technological challenge. Although progress has been steady, it may be at least 35–50 years before an operating demonstration plant is built.

Fusion occurs when the nuclei of light atoms, such as isotopes of the element hydrogen (deuterium and tritium), collide with sufficient energy to overcome the natural repulsive forces that exist between the protons of these nuclei (see Figure 8.10). When this collision takes place, a D-T reaction is said to have occurred. If the two nuclei fuse, an alpha particle, the nucleus of helium is formed with release of a neutron and lots of energy. For the fusion reaction to take place, the nuclei must be heated to a very high temperature and forced together. In a hydrogen bomb, this is done by exploding a fission bomb, uranium, or plutonium, producing the high temperature and pressure causing deuterium and tritium to fuse releasing a more powerful explosion.

Fusion reactions are possible between a number of light atoms, including deuterium alone (a D-D reaction); deuterium and helium-3, an isotope of the element helium (a D-3He reaction, see Chapter 3); and hydrogen and the element lithium, a light metal. All of these reactions occur much less frequently at a given temperature than the D-T reaction. For instance, the fusion energy produced from D-T reactions in a mixture of deuterium and tritium will be about 300 times greater than that from D-D reactions in a mixture of deuterium alone. For this reason, research into controlled fusion has concentrated on developing deuterium–tritium fueled fusion reactors.

Potential Benefits of Magnetic Fusion Energy Fuel Resources

The potential benefits of controlled fusion are many. Foremost is that in principle the fuel for a fusion power plant is essentially inexhaustible. One out of every 6670 water molecules is a deuterium atom. There are no technical barriers to extracting deuterium from water. Tritium, however, does not occur in nature. It can be produced from the element lithium, which is also abundant, although much less abundant than deuterium. To achieve the full resource potential of fusion energy will require reaching the conditions of plasma density, temperature, and confinement time necessary for energy production from reactions involving deuterium alone. As described below, these conditions are much harder to reach than for deuterium and tritium which has proved difficult enough.

Fusion researchers, however, note that even if success is reached with the D-T reaction, research will need to continue to reach power production from the D-D reaction.

Environmental and Safety Considerations

There also could be important environmental benefits from fusion. First, a controlled fusion power plant would be inherently safe. A reaction that became “uncontrolled” in such a plant would extinguish itself almost instantly with no part of the system melting and with no significant release of radioactive material. Even major accidents that could occur such as failure of the structure of a fusion power plant would not result in any radiation release. Of course, such an accident could result in significant cost because of severe reactor damage.

A second environmental benefit is that the radioactive waste products produced in a fusion plant would be less of a problem than those produced in a fission plant. Because of the nature of controlled fusion, it would be possible to reduce the long-term buildup of radioactive waste products by a factor up to a million times less that of a fission system of comparable size. The quantity of radioactive material produced in a power plant of a given size may be comparable for the two types of reactions (at least for the first generation, deuterium–tritium fusion plants), the half-life of the radioactive products from such a fusion plant would be on the order of 100 years or less. This compares to tens of thousands of years for those from a fission plant. Radioactive products from fusion plants, therefore, would decay much faster than those from fission plants, resulting in the large differences cited above. The counter-argument to this advantage of fusion is that the path to utilizing/destroying even the most dangerous radioactive products of a fission reactor is not only attainable, it has already been demonstrated as a viable technology.

More advanced fusion systems using fuel combinations that produce few or no neutrons, such as the D-3He reaction, would produce substantially less radioactive waste.

CRS-3 Paths to Fusion Energy Production

Two paths are being taken in attempts to attain controlled fusion. The first is to confine the light nuclei by a magnetic field and to heat them with an external source of electromagnetic energy. In this case, the deuterium and tritium are in a gas-like condition called “plasma.” This process is called magnetic fusion energy (MFE). The other way is to heat clusters of very small spheres containing deuterium and tritium by compressing these clusters with powerful lasers or beams of particles. Such a process is called inertial confinement fusion (ICF) and simulates—on a very small scale—the process of a hydrogen bomb. Once the reaction starts in either case, it is possible that the heat generated by the fusion reactions would be sufficient to cause other light nuclei to collide sustaining the reaction without an external energy source. Such a condition, called ignition, has not yet been reached in practice. While substantial progress has been made over the last several years in both ICF and MFE, even the least stringent condition of break-even—the point where power produced by the fusion reactions equals the power supplied by the external energy source—is still to be achieved. A fusion power plant would operate between break-even and ignition. The ratio of power out to heating power supplied would be significantly greater than break-even, but external energy would still be supplied to control the reaction rate.

By way of comparison, stars operate by using their enormous mass and gravitational force to confine the colliding nuclei. Enough heat is generated by the fusion reactions to force other nuclei to collide and undergo fusion so the reaction is sustained. Because of the large gravitational forces, these nuclei are unable to escape to the stellar region before they gain the necessary energy to fuse with one another.

Achieving break-even and power amplification would be only the first steps in the process of producing useful power. The energy from the nuclear reactions would have to be converted to another form that could be used to do work. Energy is carried away from the fusion reactions in the form of neutrons moving at high speed. Because neutrons do not have an electrical charge, they are not confined by the magnetic field and will leave the plasma region. The neutrons will give their energy up if they collide with atoms of another material, causing that substance to heat. A prime candidate for this material for future fusion power plants is the liquid metal lithium. Lithium that is heated by colliding neutrons could then transfer that heat to water, producing steam. The steam, in turn, would drive a steam turbine and generator, producing electricity. While there are no fundamental scientific barriers to this process, putting it into practice will be a complicated engineering task requiring substantial development. A second reason for using lithium is that reaction between the lithium atoms and the neutrons would produce the tritium necessary for the reactor fuel.

It is also true that the water used to transfer heat from a PWR (a fission reactor) must be stored to allow the tritium to decay before the water is released. This is in the operating manual at the Callaway Nuclear Plant.

Magnetic Fusion Energy Research

Both MFE and ICF research activities have been funded by the U.S. DOE ([http://www.doe.gov]). The ICF program currently is primarily oriented to defense applications, for simulation of nuclear weapons, although energy applications are an important part of the research effort. Nearly all of the funds for ICF research come from DOE’s Defense Programs IB91039 01-15-02 (http://www.dp.doe.gov). A major initiative of the DOE ICF program is the National Ignition Facility (NIF) (http://www-lasers.llnl.gov/lasers/nif.html) at DOE’s Lawrence Livermore National Laboratory which is currently entering the detailed engineering design stage. The NIF is primarily for weapons applications, but it will also carry out important research for potential energy production from inertial fusion.

MFE research is within DOE’s civilian programs and is located in the Office of Energy Research. Although funding for ICF research now exceeds that for magnetic fusion, the latter has been and continues to be the major fusion energy focus in the United States.

While it is difficult to predict what energy options will be available in 30, 100, or 200 years, it is with certainty that there are hundreds of years of energy available from nuclear fission using known technology and available fuel.

It may be possible for the first Generation IV reactors to be in operation by 2040—25 years from now. Several of the Generation IV reactors have been demonstrated. The CRS report estimates fusion reactors in “at least 35 to 50 years before an operating power plant is built”—fusion power production has yet to be demonstrated as viable.

There has always been a difference between what is practiced and what is known to be practical in nuclear technology. This also goes for what is being optimistically projected (for fusion) relative to what the data show is practical.

Radiological Toxicology

The radioactivity of uranium ore is often considered a threshold level of acceptable radiation. In practice, a concentrated uranium ingot can be handled with little concern of radioactive toxicology. Handling fuel pins need not be performed remotely when preparing fuel for nuclear reactors (one of the downsides of reprocessing methods is that the fuel will be radioactive and will require remote handling).

A brief introduction to radiation poisoning is necessary to understand the risks of radiation and methods for reducing risks. Both the US Environmental Protection Agency and US Nuclear Regulatory Commission (NRC) have Web sites that detail how one can be exposed to radiation poisoning and the impact of that exposer.

The following is an EPA summary on sources of radiation and radiation poisoning [6]:

What is radiation?—Radiation is energy that travels in the form of waves or high-speed particles.

When we hear the word ‘radiation,’ we generally think of nuclear power plants, nuclear weapons, or radiation treatments for cancer. We would also be correct to add ‘microwaves, radar, electrical power lines, cellular phones, and sunshine’ to the list. There are many different types of radiation that have a range of energy forming an electromagnetic spectrum. However, when you see the word ‘radiation’ on this Website, we are referring to the types of radiation used in nuclear power, nuclear weapons, and medicine. These types of radiation have enough energy to break chemical bonds in molecules or remove tightly bound electrons from atoms, thus creating charged molecules or atoms (ions). These types of radiation are referred to as ‘ionizing radiation.’

What’s the difference between radiation and radioactivity?—Radiation is the energy that is released as particles or rays, during radioactive decay. Radioactivity is the property of an atom that describes spontaneous changes in its nucleus that create a different element. These changes usually happen as emissions of alpha or beta particles and often gamma rays. The rate of emission is referred to as a material’s “activity.”

Each occurrence of a nucleus throwing off particles or energy is referred to as disintegration. The number of disintegrations per unit time (minutes, seconds, or hours) is called the activity of a sample. Activity is expressed in curies. One curie equals 37 billion disintegrations per second. (Since each disintegration transforms the atom to a new nuclide, transformation is often substituted for disintegration in talking about radioactive decay and activity.)

Exposure from radiation can occur by direct exposure, inhalation, and indigestion.

Direct (External) Exposure—The concern about exposure to different kinds of radiation varies:

• Limited concern about alpha particles. They cannot penetrate the outer layer of skin, but if you have any open wounds you may be at risk. (Note: prolonged exposure should be avoided)

• Greater concern about beta particles. They can burn the skin in some cases, or damage eyes.

• Greatest concern is about gamma radiation. Different radionuclides emit gamma rays of different strength, but gamma rays can travel long distances and penetrate entirely through the body.

Gamma rays can be slowed by dense material (shielding), such as lead, and can be stopped if the material is thick enough. Examples of shielding are containers; protective clothing, such as a lead apron; and soil covering buried radioactive materials.

Inhalation—Exposure by the inhalation pathway occurs when people breathe radioactive materials into the lungs. The chief concerns are radioactively contaminated dust, smoke, or gaseous radionuclides such as radon.

Radioactive particles can lodge in the lungs and remain for a long time. As long as it remains and continues to decay, the exposure continues. For radionuclides that decay slowly, the exposure continues over a very long time. Inhalation is of most concern for radionuclides that are alpha or beta particle emitters. Alpha and beta particles can transfer large amounts of energy to surrounding tissue, damaging DNA or other cellular material. This damage can eventually lead to cancer or other diseases and mutations.

Ingestion—Exposure by the ingestion pathway occurs when someone swallows radioactive materials. Alpha and beta emitting radionuclides are of most concern for ingested radioactive materials. They release large amounts of energy directly to tissue, causing DNA and other cell damage.

Ingested radionuclides can expose the entire digestive system. Some radionuclides can also be absorbed and expose the kidneys and other organs, as well as the bones. Radionuclides that are eliminated by the body fairly quickly are of limited concern. These radionuclides have a short biological half-life.

Shielding and the distance between the radiation emitting source and the person achieve minimizing direct exposure to radiation. Reduce the time in the presence of the radiation-emitting object. Minimizing inhalation and indigestion is achieved by keeping radioactive isotopes out of the environment. Once radiation is in the environment, the materials can be removed or isolated so the isotopes do not get into water, air, or vegetation.

The following NRC summary describes health effects upon radiation exposure [7].

Biological Effects of Radiation—We tend to think of biological effects of radiation in terms of their effect on living cells. For low levels of radiation exposure, the biological effects are so small they may not be detected. The body has repair mechanisms against damage induced by radiation as well as by chemical carcinogens. Consequently, biological effects of radiation on living cells may result in three outcomes: (1) injured or damaged cells repair themselves, resulting in no residual damage; (2) cells die, much like millions of body cells do every day, being replaced through normal biological processes; or (3) cells incorrectly repair themselves resulting in a biophysical change.

The associations between radiation exposure and the development of cancer are mostly based on populations exposed to relatively high levels of ionizing radiation (e.g., Japanese atomic bomb survivors, and recipients of selected diagnostic or therapeutic medical procedures). Cancers associated with high dose exposure (greater than 50,000 mrem) include leukemia, breast, bladder, colon, liver, lung, esophagus, ovarian, multiple myeloma, and stomach cancers. Department of Health and Human Services literature also suggests a possible association between ionizing radiation exposure and prostate, nasal cavity/sinuses, pharyngeal and laryngeal, and pancreatic cancer.

The period of time between radiation exposure and the detection of cancer is known as the latent period and can be many years. Those cancers that may develop as a result of radiation exposure are indistinguishable from those that occur naturally or as a result of exposure to other chemical carcinogens. Furthermore, National Cancer Institute literature indicates that other chemical and physical hazards and lifestyle factors (e.g., smoking, alcohol consumption, and diet) significantly contribute to many of these same diseases.

Although radiation may cause cancers at high doses and high dose rates, currently there are no data to unequivocally establish the occurrence of cancer following exposure to low doses and dose rates—below about 10,000 mrem (100 mSv). Those people living in areas having high levels of background radiation—above 1000 mrem (10 mSv) per year—such as Denver, Colorado have shown no adverse biological effects.

Even so, the radiation protection community conservatively assumes that any amount of radiation may pose some risk for causing cancer and hereditary effect, and that the risk is higher for higher radiation exposures. A linear, no-threshold (LNT) dose response relationship is used to describe the relationship between radiation dose and the occurrence of cancer. This dose-response model suggests that any increase in dose, no matter how small, results in an incremental increase in risk. The LNT hypothesis is accepted by the NRC as a conservative model for determining radiation dose standards recognizing that the model may over estimate radiation risk.

High radiation doses tend to kill cells, while low doses tend to damage or alter the genetic code (DNA) of irradiated cells. High doses can kill so many cells that tissues and organs are damaged immediately. This in turn may cause a rapid body response often called Acute Radiation Syndrome. The higher the radiation dose, the sooner the effects of radiation will appear, and the higher the probability of death. This syndrome was observed in many atomic bomb survivors in 1945 and emergency workers responding to the 1986 Chernobyl nuclear power plant accident. Approximately 134 plant workers and firefighters battling the fire at the Chernobyl power plant received high radiation doses—80,000 to 1,600,000 mrem (800 to 16,000 mSv)—and suffered from acute radiation sickness. Of these, 28 died within the first three months from their radiation injuries. Two more patients died during the first days as a result of combined injuries from the fire and radiation.

Because radiation affects different people in different ways, it is not possible to indicate what dose is needed to be fatal. However, it is believed that 50% of a population would die within thirty days after receiving a dose to the whole body, over a period ranging from a few minutes to a few hours, between 350,000 to 500,000 mrem (3500 to 5000 mSv). This would vary depending on the health of the individuals before the exposure and the medical care received after the exposure. These doses expose the whole body to radiation in a very short period of time (minutes to hours). Similar exposure of only parts of the body will likely lead to more localized effects, such as skin burns.

Conversely, low doses—less than 10,000 mrem (100 mSv)—spread out over long periods of time (years to decades) don’t cause an immediate problem to any body organ. The effects of low doses of radiation, if any, would occur at the level of the cell, and thus changes may not be observed for many years (usually 5–20 years) after exposure.

Genetic effects and the development of cancer are the primary health concerns attributed to radiation exposure. The likelihood of cancer occurring after radiation exposure is about five times greater than a genetic effect (e.g., increased still births, congenital abnormalities, infant mortality, childhood mortality, and decreased birth weight). Genetic effects are the result of a mutation produced in the reproductive cells of an exposed individual that are passed on to their offspring. These effects may appear in the exposed person’s direct offspring, or may appear several generations later, depending on whether the altered genes are dominant or recessive.

Although radiation-induced genetic effects have been observed in laboratory animals (given very high doses of radiation), no evidence of genetic effects has been observed among the children born to atomic bomb survivors from Hiroshima and Nagasaki.

Energy Efficiency in the Nuclear Energy Industry

Providing a sustainable source of energy is a universal goal for all nations. The world population continues to grow and an adequate energy supply must be in the plans to maintain or improve the quality of life. Sustainability is a strategy to meet the energy needs of the present generation and increase our ability to serve the demands of future generations.

There are more than 437 nuclear power plants that currently provide about 11% of the world’s electricity. In the United States, about 19.5% of the electricity is produced with 99 nuclear power plants [8,9]. There are 66 plants under construction in the world—five of them in the United States. Most of these new plants will be Generation III designs modified to improved energy efficiency, safety, and proliferation security.

Today, nuclear energy represents a commitment to the production of electricity. This recommends there be a plan for the future. Such a collaborative was formed in 2006 called the Global Nuclear Energy Partnership charged to develop and deploy advanced nuclear fuel cycle technologies. This program faltered and has been replaced by the International Framework for Nuclear Energy Cooperation in June 2010 [10].

Under this plan, recycling spent nuclear fuel will greatly reduce the amount of “nuclear waste” destined for disposal. This program will require advanced Generation IV fast neutron flux reactors that use the transuranic (elements beyond uranium in the periodic table—this includes plutonium) as fuel. Experimental fast flux reactors have demonstrated long lived fission products can be transmuted (change their atomic number and reduce or eliminate their radioactivity) by exposure to fast neutrons.

The early nuclear reactor technology has been proven reliable and economic on a commercial scale without the environmental impacts of fossil fuel power plants. Fossil fuel power plants (burning coal and natural gas) contribute the major fraction of our electric power but they are also major sources of the increasing concentration of greenhouse gases in the atmosphere. The sustainable future of nuclear power depends on improving the technology for new energy systems to replace old nuclear plants as they are retired from service.

New generation nuclear power plants will need to meet the performance standards on safety, low environmental impact, and competitive prices. Since all of these standards are measured per kWh of electrical power produced, improved thermal efficiency is a win–win situation and will be discussed first. After a discussion of thermal efficiency, the Generation IV designs will be reviewed. Finally, the lessons history offers will be discussed.

As the name “heat engine” implies, heat engines are based on methods of converting high-temperature energy (heat) into work and discharging low-temperature heat. The illustrative example of Figure 8.11 is for a steam cycle operating at 33% thermal efficiency. For every 100 kW of high temperature heat going into the engine, 33 kW of work is produced and 67 kW of waste heat is rejected into the environment. As illustrated by the following equation, thermal efficiency is defined as the net work produced divided by the heat input from the high-temperature reservoir. An energy balance on a power plant also allows the thermal efficiency to be written in terms of the heat at high temperature and heat rejection at low temperature.

(8.1)

The majority of advances in heat engine technology targets increasing the thermal efficiency. A French engineer Nicolas Leonard Sadi Carnot (1796–1832) recognized that the thermal efficiency of a heat engine increased with increasing temperatures of the heat input and decreasing temperatures of the heat rejection. The best possible efficiency for a given source of heat and reservoir for rejecting heat is the Carnot cycle. The Carnot cycle is a reversible heat engine operating from hot and cold reservoirs at constant temperatures of TH and TL, respectively. Equation 8.2 provides the thermal efficiency of the Carnot cycle where the temperatures are in degrees Kelvin, the absolute temperature scale.

(8.2)

Equation 8.2 indicates that as the temperature of heat input in a power cycle increases, the thermal efficiency increases. This trend is verified by the historic data of Figure 8.12 that shows the evolution of the steam power cycle (typically coal fired).

For large commercial power plants, TL is fixed by the environment, (often a river, lake, or a cooling tower) because it is the only place large enough to take in vast amounts of heat without an increase in temperature. Heat rejection during warm summers increases TL in Equation (8.2), and this lowers the efficiency. A major component of power plants are the cooling towers that circulate and evaporate water to provide a practical low temperature place to reject the low temperature heat from the steam turbine.

Most locations have climates that allow the cooling water heat rejection at 40°C or less year round. Because the heat rejection temperature is controlled by local climate, the only degree of freedom in the Carnot cycle equation for increasing efficiency is to increase the high-temperature energy source (TH).

Figure 8.13 illustrates the basic steam cycle. The generator is driven by the turbine and produces electrical power. Steam is condensed by cooling it in the condenser—the flow of cooling water through the condenser results in a heat rejection to the surroundings. The heat input occurs in a boiler (not shown). The boiler produces steam that is directed to the turbine(s), and this steam is returned to the boiler in the form of liquid water with a pump to overcome the pressure drop through the turbine(s). The work put into the pump is small compared to the power produced by the turbines resulting in a net production of electrical power.

In practice, TH is the highest temperature that a working fluid reaches in a power cycle. This is usually the temperature of the working fluid as it leaves the heat exchanger producing the steam just prior to expansion in the turbine. In a nuclear reactor, the maximum temperature occurs when the working fluid is in contact with the fuel rods; in a natural gas power plant it is the combustion temperature; and in a pulverized-coal-fired power plant it is the temperature of steam as it exits the steam super heater.

In practice, heat input is not at a constant temperature since the working fluid increases in temperature as it is heated (or as combustion takes place with a gas turbine). The Joule efficiency is defined to take into account that practical engines do not operate with all heat input at a constant temperature. Equation 8.3 defines the Joule efficiency.

(8.3)

Because the Joule efficiency does not account for process irreversibility, further modification is needed to correlate with actual processes. A correlation effective for the historic data of Figure 8.12 applies an overall reversibility factor (f) that indicates that the low-temperature heat rejection increases with increasing irreversibility. This empirical formula is provided by Equation 8.4.

(8.4)

Figure 8.14 compares the historic data with Equation 8.4 and a reversibility factor of f=0.77 represents the performance of the steam power cycle.

In the correlation of Figure 8.14, TLavg was taken as 313 K (40°C) and THavg was the arithmetic average of the boiler feed temperature and the turbine inlet temperature. Based on this correlation, the efficiency increases with the average temperature at which heat is received by the working fluid. Implicit in this correlation is that good design practices and efficient turbines/pumps are used. The reversibility factor of 0.77 is obtained with state-of-the-art turbines and pumps as well as designs where the minimum approach temperatures for heat exchangers is low, about 10°C.

Practical Brayton power cycles fueled with natural gas depend on materials development increasing the temperatures at which the metals of turbines can operate and large heat exchangers can be economically manufactured. As illustrated by the trends in boiler feed temperature of Figure 8.12, regenerative heating of the working fluid is just as important as increasing turbine operating temperatures to increase THavg and the thermal efficiency of the power cycle.

After partial expansion of the steam, some of it is diverted to feed water heaters. This feed water heating uses the lower quality energy of partially expanded steam rather than heat provided by combustion or the nuclear reactor. Moving from 17% to 42% thermal efficiency, the number of heaters increased from 2 to 8 or more. Higher pressures are necessary to increase the boiler feed temperature above 290°C—the higher pressures required reheat of the steam after expansion through the high pressure turbine. Moving from 17% to 42% thermal efficiency required reheating the steam two times as it moved from the inlet high pressure to the turbine exit pressure.

Figure 8.15 shows a steam cycle with one steam reheat and one feed water heater. When steam is produced at higher pressure, a steam reheat is used to keep excessive water from condensing in the turbine. Excessive condensation leads to erosion of the turbine blades and failure of the turbine. Reheating the steam before completing expansion in the low-pressure turbine avoids the excessive condensation problem and provides additional high-temperature heat input that increases the thermal efficiency.

Both open and closed feed water heaters can be used to preheat the boil feed water. A small amount of condensing steam heats the feed water to the temperature of the steam. Higher steam pressures, repeated steam reheat, and multiple feed water heaters were all needed in the evolution of the steam cycle to achieve the higher THavg and converting more heat to work.

Figure 8.16 superimposes the increases in Carnot, Joule (TLavg=313 K), and modified Joule (f=0.77) efficiencies as the working fluid (steam) temperature increases. Nuclear and coal-fired power plants closely follow the modified Joule curve since the reversibility factor of 0.77 is characteristic of current turbine and regenerative heat-transfer efficiencies. Natural gas combined cycles do not follow the modified Joule curve because the lost work associated with air compression and heat transfer to the low temperatures cycle are inefficiencies of the combined cycle that are not included in the inefficiencies of the steam cycle.

Figure 8.17 shows the (based on the modified Joule equation) performance potential for the steam cycle and combined cycles. The correlation in Figure 8.17 represents the goals for the new Generation IV reactors. The higher nuclear reactor temperatures produce higher thermal efficiency producing electricity from nuclear power. Higher thermal efficiencies yield reductions in both capital and fuel costs for the nuclear power system.

Steam Cycles in Commercial Operation

The concepts for improved efficiency of heat engines are well known. It is the practical design limitations of current nuclear boiling water reactors (BWRs) and pressurized water reactors (PWRs) that limit the thermal efficiency of these nuclear power plants.

For comparison, Figure 8.18 illustrates a pulverized coal-fired power plant. Coal is ground into powder so that when it is introduced into a flame it burns similar to a spray of liquid fuel. The hot flue gases rise from the flames to steel pipes in the upper section of the fire box that comprise the boiler, super heater, and steam re-heater of the power plant steam generator. The steel piping contains the liquid, vapor, and supercritical fluids passing through the boiler.

The materials used to fabricate the pipes limit the high temperature and pressure of the steam generator. Multiple steam reheats can be placed between the partially expanded steam flow as it passes between the stages of the steam turbine.

Boiling Water Reactors

Figure 8.19 is a diagram of a nuclear BWR. Water enters the reactor, preheated by the feed water heaters (to about 150°C, not shown). Both the pressure and temperature in the reactor are maintained below the critical points of water (374°C, 221.MPa). The operating temperature is set near 286°C and the pressure near 70 MPa.

The water surrounding the fuel rods in the core of the BWR must be maintained as liquid because the core is designed for water to serve as the neutron moderator (slow the neutrons). The core is designed to operate with the neutrons dissipating most of their energy (velocity) through collisions with water molecules before colliding with nuclear fuel. If water vapor bubbles are present an insufficient number of collisions with water occur and the neutrons have too high an energy to produce fission, and the nuclear fission reaction will not be self-sustaining. While this is a desirable feature in case of pump failure, normal operation requires that liquid water surround the fuel rods. In a BWR, the fraction of vapor in the core can be adjusted by changing the circulation rate of water through the core, the water circulation rate works to control the nuclear fission rate.

BWR systems employ high-volume jet pumps (not shown) to assist the circulation of water through the reactor core. Steam is formed, but the high water circulation rate rapidly carries the steam to the top of the reactor vessel where it is separated from the water and flows to the steam turbines.

Steam leaving the BWR is usually saturated. At saturated steam near 286°C, expansion through a (condensing) turbine produces liquid water. This water must be removed when about 10% in the steam condenses. As illustrated in Figure 8.19, the BWR power cycle uses staged expansion to remove the condensed steam in a separator (~188°C) rather than as a means to superheat the steam to attain higher efficiencies. Heating this 188°C saturated steam with 286°C primary steam produces a superheated steam that can then be expanded through the turbine.

The THavg of the BWR is quite low at about 218°C; however, the thermal efficiencies are about 33%.

Pressurized Water Reactors

The PWR uses a closed cycle with water in a isolated, pressurized water loop circulated between the reactor core and heat exchangers that produce steam for the steam turbine power cycle. Figure 8.20 is a schematic diagram of a PWR. Borate (boric acid) is added to this water to absorb neutrons during the early part of new fuel cycle. As fission products build up in the fuel, they absorb neutrons and the borate concentration is reduced to maintain uniform power production. The water remains liquid under pressure and leaves the reactor at 315°C and 150 bar (the bubble point pressure of water is 105.4 bar).

The closed cycle design of PWR all but eliminates possible radioactive contamination of the power cycle’s working fluid (steam/water). If there is a leak in a fuel rod the radioactive “fuel spill” is contained in the reactor cooling water loop. This keeps the radioactive elements for the steam turbine—a “mess” to decontaminate. This is one reason, commercial PWRs outnumber commercial BWRs by about 3:1.

A boiler, super heater, and reheat are used with the BWR similar to a coal-fired facility, but operating at lower temperature and pressure. In principle, the PWR reactor can attain higher efficiencies than the BWR, but the extra water circulation loop limits the upper end of the efficiency at about 33%.

Generation IV Nuclear Power Plants

The light water reactors (BWR and PWR) are Generation II reactor designs with the BWR and PWR comprising 90% of the nuclear reactors in the United States and 80% of the nuclear reactors in the world. Table 8.12 lists the most promising of the Generation IV reactors along with typical maximum temperatures for the power cycles associated with each design.

Table 8.12

Summary of nuclear reactor designs and operating temperatures

| System | Abbreviation | Typical Tmaxa (°C) | Fast flux |

| Generation II | |||

| Boiling water reactor | BWR | 288 | No |

| Pressurized water reactor | PWR | 300 | No |

| Generation IV | |||

| Gas-cooled fast reactor system | GFR | 850 | Yes |

| Lead-cooled fast reactor system | LFR | 540/790 | Yes |

| Molten salt reactor system | MSR | 680/780 | Other, with full actinide recycle |

| Sodium-cooled fast reactor system | SFR | 540 | Yes |

| Supercritical-water-cooled reactor system | SCWR | 510/540 | Option |

| Very-high-temperature reactor system | VHTR | 990 | No |

aTemperatures are for working fluid in the power cycle. A 10°C minimum approach temperature is assumed for each heat transfer process for the indirect systems.

This table shows that the anticipated maximum cycle temperatures will be over 500°C; each of these Generation IV systems will attain thermal efficiencies in excess of 40%. Thermal efficiencies up to 50% are possible with the higher temperature systems. This means that a 1 GW power plant becomes a 1.3–1.5 GW power plant using the same amount of fuel.

Generation IV Reactor Systems

The early or prototype nuclear power reactors built in the 1950s and 1960s are classified as Generation I energy systems. This experience provided the technology improvement to the Generation II light water moderated reactors. These were deployed in the 1970s and are most of the commercial reactors in the United States today. The evolution of these designs with advances in control, safety, and economics make up the Generation III light water reactors that have been deployed outside the United States in the 1990s. An indication of the success of nuclear reactors deployed in the United States is the numbers from 2002: They produced 790 billion kilowatt-hours of electricity at an average cost less than 1.70 cents per kilowatt-hour. Three billion tons of air emissions would have been released by fossil fuel plants producing this electrical energy in 2002 [11]. This historical record drives the plan that the future of energy sources move toward nuclear energy replacing fossil fuels. These are designated Generation IV nuclear energy systems.