19

Dewatering of Industrial Sludge in Sludge Treatment Reed Bed Systems

S. Nielsen and E. Bruun

Orbicon A/S, Ringstedvej 20, Roskilde, Denmark

19.1 Introduction

Sewage sludge results from the treatment of wastewater originating from many sources including homes, industries, agro-industries and street runoff. Sewage sludges contain nutrients and organic matter and, due to these soil benefits, they are widely used as soil amendments. The beneficial effects of sludge application for agriculture and/or environmental purposes (forestry and land reclamation) are well known and documented (e.g., [1] and references therein). The use of organic wastes in agriculture is considered a way of maintaining or restoring the quality of soils, enlarging the slow cycling soil organic carbon pool. Sewage sludge, however, also contains contaminants including metals, pathogens, and organic pollutants [1, 2]. A wide variety of undesired substances, such as potentially trace elements and organic contaminants, can have adverse effects on the environment.

The production of sewage sludge has increased steadily, due to the growth of population connected to centralized wastewater treatment and the implementation of more strict environmental regulation [3]. For example, the yearly production of municipal sludge in the European Union (EU) – estimated to 5.5 million tons in 2005 – is expected to reach a production of 13 million tons of dry solid (t ds) by 2020 [4]. Sludge production from industry, food-industry and agriculture has simultaneously increased during the same period. By 2020, all waste in EU should be managed as a resource and landfilling of organic material should be virtually eliminated [4]. In order to achieve this for sewage sludge and to avoid landfilling or incineration, eco-sustainable technologies are necessary.

There are several technologies for sludge treatment (dewatering) in the market, ranging from traditional mechanical treatment by decanter and screw-press technology to the environmentally friendly, Sludge Treatment Reed Bed Systems (STRB). Sludge Treatment in Reed Bed Systems was developed in the late 1980s and has been providing a low cost and maintenance option for sludge dewatering and stabilization, at both small and larger treatment works [5, 6].

There are important differences in the environmental perspectives and costs involved in mechanical sludge dewatering followed by disposal on agricultural land compared to STRB. The capital cost of the STRB is typically higher than mechanical options, while the reverse is true for the system operating costs. A study by Nielsen [7], who compared the costs of mechanical treatment with STRB treatment of activated sludge (sludge production: 550 tons ds/yr) showed significant lifetime cost savings using a STRB solution when compared to a mechanical solution [8].

In order to compare the two treatment methods, sizing, capital and operating cost and power use estimates were developed for comparison purposes (under Danish conditions). The study showed that a sludge strategy consisting of a new STRB would be approx. DKK 0.5–0.6 million cheaper per year than the option consisting of a new screw press or decanter, for sludge treatment and final disposal to agricultural land. Besides these economic benefits, and on the other hand to mechanical solutions, the STRB systems are also environmentally friendly, as the dewatering of sludge in STRB occurs without the use of chemicals and with a minimum of energy [8].

Sludge Treatment Reed Bed Systems are vertical flow constructed systems for the dewatering and stabilization of sludge. Sludge is loaded to the basins, which are typically vegetated with common reeds (Phragmites australis or Typha), and dewatered through passive drainage and evapotranspiration. Treatment of wastewater sludge in STRB is a widespread and common WWTP sludge treatment practice for both civil and industrial sludge in Europe. In Denmark the technology has been used for more than 28 years. The method for treatment and dewatering of sludge may influence the sludge quality considerably. For example STRB's are capable of degrading/reducing the concentrations of hazardous organic compounds, such as LAS, NPE, DEHP, and certain PAH's to a much higher degree than traditional mechanical treatment methods [9].

Many sludge types can be treated by the STRB technology including activated sludge or digested sludge, and waterworks (WW) sludge. Experience has shown that STRBs are capable of treating sludge with different qualities and with dry solid concentrations between 0.1% and up to 5% [10].

During the 1990s and onwards, stricter legislation has been brought into effect by the Danish Environmental Protection Agency (DEPA) to regulate the content of nutrients, heavy metals and hazardous organic compounds in sludge being spread on agricultural land [9]. In order to apply sludge on farmlands in Denmark the following criteria for the sludge quality have to be fulfilled (Table 19.1).

Table 19.1 The Danish and European Union (EU) legal limits for heavy metals and hazard organic compounds in sludge residue for agricultural use.

| Limit values | Denmark | EU | ||

| BEK No. 1650 of 13/12/2006 | 86/278/EE EU Directive | ENV. E 3 (2000) Working document on sludge, 3rd draft | ||

| Heavy metals | mg/kg ds | mg/kg TP | mg/kg ds | mg/kg ds |

| Cadmium (Cd) | 0.8 | 100 | 20–40 | 10 |

| Copper (Cu) | 1,000 | – | 1,000–1,750 | 1,000 |

| Nickel (Ni) | 30 | 2,500 | 300–400 | 300 |

| Lead (Pb) | 120 | 10,000 | 750–1,500 | 750 |

| Zinc (Zi) | 4,000 | – | 2,500–4,000 | 2,500 |

| Mercury (Hg) | 0.8 | 200 | 16–25 | 10 |

| Chromium (Cr) | 100 | – | – | 1,000 |

| Organic CONTAMINANTS | mg/kg ds | mg/kg TP | mg/kg ds | mg/kg ds |

| LAS | 1,300 | – | – | 2,600 |

| PAH | 3 | – | – | 6 |

| NPE | 10 | – | – | 50 |

| DEHP | 50 | – | – | 100 |

This chapter describes the experiences and results from STRBs and test systems treating industrial sludge with special focus on treatment of water works sludge. Industrial sludge may contain pollutants such as heavy metals, nutrients, hazardous organic compounds or fat in higher concentrations than domestic (household) sludge and is therefore often more difficult to treat and dewater or to dispose after treatment due to legal regulations.

19.2 Methodology

19.2.1 Description of an STRB

Sludge Treatment in Reed Bed Systems are vertical flow constructed systems for the dewatering and stabilization of sludge. Sludge treatment reed beds comprise a series of basins, which are vegetated typically with common reeds (Phragmites australis) in a filter [10]. The sludge residue remains on the surface of the filter in the basins and is mineralized through the natural biophysical interaction of plants, microbes and air, whilst water is removed from the sludge by both evapotranspiration and drainage through the sludge residue and filter (Figure 19.1) [10].

Figure 19.1 Cross-section of a STRB showing the sludge layer, filter and loading and drainage system (Copyright Orbicon, reproduced with permission).

Vegetation and ventilation with air in STRB systems create favorable conditions for the transformation of degradable organic matter to a more stable humic form [11, 12]. As the organic matter mineralizes, the overall sludge volume reduces and the accumulating sludge residue becomes continually part of the filter in which the reeds grow. The height of the mineralized sludge residue layer increases with time with an accumulation rate of approximately 10–15 cm/yr, depending on the sludge quality. After typically 8 to 12 (up to 20) years of operation, the dewatered and mineralized sludge residue is excavated from the STRB basins and recycled as fertilizer or as soil conditioner.

Currently, STRBs are used primarily for treatment of sewage sludge from municipal wastewater treatment plants (WWTP), but the technology is also used for the treatment of water works (WW) sludge and sludge originating from the agro-industrial production. However, some types of sludge may not be suitable for dewatering in a STRB, e.g., if the sludge has a high concentration of fat and oil. Experience has shown that STRBs are capable of treating most types of sludge with dry solid concentrations between 0.1–5%.

19.2.2 Description of STRB Test-System

The dewatering and treatment efficiency of sludge in STRBs depends on the sludge quality, and the design and operation of the STRB. Before planning and establishing of new full-scale STRB plants, it is strongly recommended to test the sludge's dewatering properties in a test system with similar filter and setup as the intended full-scale system [7]. A test of the dewater ability of the sludge is especially important, if it is not ‘normal’ sludge from households, but industrial sludge with, for example, a high content of fat, oil, organic material or heavy metals.

In Denmark, Germany, Sweden, France and other countries in Europe the design and dimensioning of STRBs has been extremely variable during the last 20 years, even if they were treating the same sludge type. The number of basins in the different systems varied between 1–24 basins, basin areas between less than 100 m2 to over 3,000 m2 and the area load varied between 30 to over 100 kg ds/m2/yr [7]. Consequently, the outcome of the sludge treatment has also varied. If the STRB has been properly designed and operated, high dry solid contents in the sludge residue has been obtained, while the opposite has been true at poorly designed and operated STRBs [9]. Some sludge types are difficult to dewater by both STRB and mechanical treatment technology.

A test system consists typically of 3–6 pilot-scale basins of 1–2 (up to 100) m2 with filter, drain layer, drains, growth layer and reeds (Phragmites). During the trial period of typically 4–12 months (sometimes it is necessary with 2 years), each basin is loaded several times, followed by a resting period, where no sludge is added. The length of the loading and rest periods depends on the sludge characteristics, climate (cold climates need longer resting periods), and the age of the system and specific basin, the dry solid content and the thickness of the sludge residue.

The main purpose of a test (phase 1) is to test whether the sludge would be suitable for further treatment in a STRB or not [7]. This will be answered by gathering information about:

- Sludge quality and characteristics.

- Dewatering efficiency of the sludge (L/sec/m2).

- The sludge residue behavior (dry/crack up) in a trial bed.

- The growth of reeds. Is it possible to get the vegetation to grow in the sludge?

Later on in the test period in phase 2 the loading onto the reed beds will be much more intensive. Loading rates will vary in the test period so that the differences in load/rest ratio and area load can be more clearly defined. Different numbers of loading days and resting days will be tested. The main purpose in phase 2 is to test (ascertain the criteria) for the dimensioning and operation of a full-scale system [7]. For example:

- What loading (kg dry solid/m2/yr) can the trial system treat?

- The number of basins that is necessary in order to get the desired resting period between loadings.

- How many days can we load in a loading period?

- How many days rest are necessary for drainage and drying (min and max)?

- Load and rest program in relation to sludge quality.

- Determine sludge residue and filtrate water quality.

- Summer and winter operation.

- Determine the sludge quality.

- Determine sludge residue and filtrate water quality.

- Finally, to give recommendations for up-stream changes on the works in order to reduce unwanted parameters in the feed sludge (e.g., heavy metal, fat and oil etc.)

19.3 Treatment of Industrial Sludge in STRB Systems

There is no sharp definition of “industrial sludge”, but the term encompasses sludge originating from wastewater treatment at the industry's own wastewater treatment plant or sludge produced at a public WWTP with a large proportion of wastewater originating from industry and agro-industrial sludge. Treatment of wastewater from “industries”, such as the food industry, aquaculture and waterworks, generates sludge that typically contains pollutants not present or in much higher concentrations than in normal sludge derived from domestic wastewater. These sludge types may be problematic and result, e.g., in reduction of the sludge dewatering, inhibition of reed growth or contamination of the sludge residue.

Examples of problematic compounds in sludge includes organic material such as fat and oil, heavy metals, nutrients such as phosphate and nitrate, and hazardous organic compounds – these are described in the following sections.

Of the different industrial sludge types, water works sludge typically have high content of iron or aluminum, but low content of organic material and fat and oil. Sludge generated from treatment of wastewater from the food industry (abattoir, dairies, aquaculture etc.) typically has a high proportion of organic material (carbohydrates, fat, oil, protein), heavy metals and nutrients (nitrogen and phosphorous), with high values of BOD (biological oxygen demand), COD (chemical oxygen demand) and suspended solids. Due to these constituents, the food industry sludges have a high potential to cause severe pollution problems to the environment.

19.3.1 Organic Material in Sludge

Insufficient dewatering of sludge in an STRB and in mechanical dewater equipment also, is often due to the quality of the sludge and sludge residual. The ratio between organic and inorganic material is an important parameter in the evaluation of sludge dewatering properties [9]. The organic content is determined typically by measuring the ‘Loss on Ignition’ (LOI).

The water retention capacity of sludge with a high proportion of organic material is many times larger than more inorganic sludge, as the content of organic material has major influence on the content of free water. The higher the organic material, the lower the content of free water and the higher the content of capillary water [20], which is more difficult to dewater [21].

When comparing the feed sludge's content of organic material (expressed as LOI) with the corresponding dry solid content in the sludge residue for a large number of STRB basins, there is a clear tendency that higher contents of organic material in the feed sludge results in lower dry solid contents in the sludge residue in the STRB (Figure 19.2).

Figure 19.2 Correlation between organic content (loss on ignition) in the feed sludge and the dry solid in the sludge residue in the STRB [21]. Experience has shown that a LOI above 65% significantly reduces the dewatering of the sludge [21].

19.3.2 Fats and Oil in Sludge

An important visual indication of a proper dewatering of the sludge is that the upper layer continually becomes cracked and broken during the resting phase. Sludge containing a high proportion of fats and oil often has a tendency not to crack and break open during the resting phase, reducing thereby the aeration from the surface considerably. If this cracking does not occur, it is due to ineffective dewatering of the sludge [21].

A high content of fats and oil in the feed sludge is especially important to address and reduce, since this, like organic material, has a pronounced effect on the dry solid content in the sludge residue in the STRB (Figure 19.3). Experience has shown that a fat content in the feed sludge above 5,000 mg/kg ds considerably reduces the dewatering and results in pronounced anaerobic conditions in the sludge residue, which becomes black and smelly [21].

Figure 19.3 Correlation between content of fat in the feed sludge and the dry solid content in the sludge residue [21].

19.3.3 Heavy Metals in Sludge

Depending on the industry producing the wastewater, high contents of heavy metals may be present in sludge. The concentration of heavy metals may fluctuate over time, due to changes in the production at the industry producing the wastewater. Sludge, which normally has low levels of heavy metals below legal limits, may, e.g., if new industry is connected to the WWTP, rise to levels inhibitory for reeds or reach levels in the sludge residue, which exceed legal limits for agricultural use (Table 19.1).

Experience from Denmark has shown that the level of heavy metals in the sludge residue after 10 to 20 years of treatment in STRBs is in general low – well below the Danish and EU legal limit values [22]. Heavy metals are mainly bound to particles in the sludge residue and filter matrix, and the translocation of heavy metals out of the systems with the drainage is, therefore, limited [11, 15, 22, 23]. A study by Stefanakis and Tsihrintzis from 2012 [24] about heavy metals in an STRB showed that the major sink in the mass balance for heavy metals was the gravel drainage layer, while accumulation in the sludge layer and plant uptake was low. Less than 16% of the heavy metals left the bed through drainage. In Denmark, there have been cases with reeds dying out due to nickel pollution in the sludge residue at a WWTP with connected heavy industry.

19.3.4 Nutrients in Sludge

The sludge residue from an STRB is valuated as a fertilizer, since the phosphorus and nitrogen concentration is typically high due to anthropogenic origin of the sludge [25]. Nitrogen typically decreases during the treatment period and with the depth of the sludge residue in the basins, due to the microbial mediated processes of nitrification and denitrification [11]. In addition, some nitrogen leaves the system with the drainage water (filtrate water) mainly in the form of nitrate and is returned to the WWTP.

Total phosphorous concentration has been shown to increase for the whole sludge residue in an STRB compared to the feed sludge [15], due to the mineralization of organic material in the sludge residue. Part of the phosphorous interacts with iron and other constituents in the sludge and is, thus, bound in the sludge residue matrix.

19.3.5 Hazardous Organic Compounds in Sludge

Various hazardous organic compounds may be present in sludge, such as polyaromatic hydrocarbons (PAHs), di-2-ethylhexyl-phthalates (DEHPs), nonylphenol/nonylphenol ethoxylates (NPEs), linear alkyl benzene sulfonates (LASs), originating, respectively, from coal and tars, lubricating oil additives and detergents. Studies have shown that hazardous organic compounds are mineralized during the treatment in STRB [9, 26]. Unlike traditional mechanical dewatering, such as centrifuges, the long treatment time of the sludge residue in STRBs (typically 8–10 years or more) provides sufficient time for microbiological and non-biotic mineralization processes to effectively degrade and reduce most of the hazardous organic compounds. Even within a shorter timespan of 3–6 months, significant reductions have been shown [8, 22].

In a study of the mineralization of LAS and NPE in digested sludge treated in an STRB, a degradation of 98% of LAS and 93% of NPE was obtained under aerobic conditions ([9]; Danish Environmental Agency: Report no. 22, year 2000). The study showed that oxygen was the limiting factor in the degradation of the organic contaminants. Oxygen influx into the sludge improved the mineralization of LAS and NPE considerably, while mineralization under anaerobic conditions was very limited. In the same study, reductions of approximately 60 and 32% in an STRB were obtained for DEHP and PAH, respectively. The organic contaminants were not only mineralized in the upper layer of sludge residue, but in the whole depth. In storage experiments with anaerobically digested sludge (representing mechanical treatment) LAS, NPE, DEHP and PAH were only partly degraded in the top layer (0–20 cm) and below 20 cm, no degradation occurred.

19.4 Case Studies – Treatment of Industrial Sludge in Full-Scale and Test STRB Systems

The following sections present cases and results from treatment of sludge from water works and industry.

19.4.1 Case 1: Treatment of Industrial Sewage Sludge with High Contents of Fat

The industrial sewage sludge originates from WWTP treatment of wastewater with a large input from industry. Table 19.2 presents Danish STRBs systems treating sludge originating from treatment of wastewater with major input from industry: Tinglev STRB (abattoir), Kolding STRB (abattoir), Skagen test STRB (fishing industry), Skive STRB (abattoir) all Danish STRBs and in Kristianstad (Sweden) test STRB receiving sewage water from the food industry (dairies, abattoir representing (20–25%), chicken and others). These systems all receiving sludge with a high proportion of organic material. The sludge quality was characterized by a high loss of ignition (between 65 and 76% of dry solids), and with high contents of fat (15,000–30,000 mg/kg ds) and oil (2,300–7,000 mg/kg ds). Results of dewatering from these STRB systems are presented in Table 19.2 [21].

Table 19.2 Dewatering efficiency in relation to the sludge – and sludge residue quality [21]. All examples below has feed sludge with high levels of fat.

| Dewatering | Dry solid (%) | Loss on ignition (%) | Fat in feed sludge | ||||

| STRB system | Major WW source | L/sec/m2 | Sludge | Sludge residue | Sludge | Sludge residue | mg/kg DS |

| Tinglev (F) | 1 | 0.002–0.005 | 0.4–0.6 | 10–15 | 75 | 70 | 21,000 |

| Kolding (F) | 1 | 0.002–0.008 | 0.5–1.0 | 15–25 | 65 | 60 | 30,000 |

| Skive (F) | 1 | 0.001–0.004 | 0.8–1.2 | 2.9–7.1 | 76 | – | 15,000 |

| Skagen (T) | 2 | 0.001–0.003 | 0.5–3.0 | 5–14 | 75 | 80 | 16,000 |

| Kristianstad (T) | 3 | 0.003–0.020 | 0.5–2.5 | 8–14 | 70 | 75 | 29,000 |

Major wastewater source: (1) abattoir; (2) Fishing Industry; (3) Food-Industry (dairies, abattoir representing 20–25 %), chicken and others.

F: Full-scale; T: Test STRB.

The high contents of fat and oil resulted in a dewatering profile with a maximum level approximately five to ten times lower (only 0.001–0.004 L/s/m2) than observed for normal sewage sludge (Figure 19.4) in a well-functioning STRB system (Helsinge STRB in Denmark) typically with maximum levels of 0.015–0.020 L/s/m2 (Figure 19.4). It has been shown that dewatering of sludge with LOI between 50 and 65% will have a maximal drainage in the order of 0.008–0.020 L/s/m2 [21].

Figure 19.4 (A) Dewatering curve from Helsinge STRB and (B) Tinglev STRB. Helsinge STRB has a good dewatering of the sludge, while Tinglev STRB has a very low dewatering [21]. With permission of Obricon.

Sludge qualities with high contents of fat and oil often result in dewatering profiles, where the maximum level of the dewatering is very low and the dewatering does not decline to zero between the loads and after the last load, but has a long “tail” continuously remaining at a certain level until the next sludge load period of the specific basin. This means that the sludge residue in that basin does not have a resting phase in between loads, resulting in an anaerobic wet sludge residue.

19.4.2 Case 2: Treatment of Industrial Sewage Sludge with High Contents of Heavy Metal (Nickel)

It is important to follow the feed sludge quality on a continuous basis, with regular sampling and analyses. If heavy metal concentrations, e.g., of nickel or another heavy metal exceeds the national legal limits (Table 19.1) for recycling sludge to agriculture in the feed sludge loaded to a STRB, the sludge residue cannot be applied on agricultural lands, but has to be deposited on a landfill or incinerated, which is much more expensive [22]. Potential inhibition of the reed growth or toxic effects is another reason for keeping a close eye on the sludge quality, here under the content of heavy metals in the feed sludge.

The Danish STRB (Stenlille) is an example of an STRB which has received sludge with high nickel levels (Figure 19.5). The vegetation (Phragmites) in the basins was visibly not thriving with thin yellow new shoots. The Danish national legal limits for sludge applied to agricultural lands is 30 mg/kg ds (Table 19.1).

Figure 19.5 Basin containing Nickel polluted sludge. Note the yellow color and poor reed coverage (06-06-2011) (Photo: Orbicon).

Figure 19.6 Nickel concentrations (mg Ni/kg DS) measured in the feed sludge during the period from 2006–2012. The Danish national legal limits for Nickel in sludge applied to agricultural lands is 30 mg Ni/kg DS (Gray line).

As can be seen in Figure 19.6, nickel in the feed sludge was on most occasions several times higher than the national limit (red line in Figure 19.6). Research has shown that nickel concentration in the reeds of more than 5 mg/kg ds may cause toxic effects on the plants [27]. The reeds at the specific STRB site had nickel concentrations of 9.7 mg/kg ds (Table 19.3).

Table 19.3 The result of nickel analyses of reeds (Phragmites australis), and sludge residue sampled at different depth intervals.

| Nickel concentration | mg Ni/kg ds |

| Reeds (Phragmites) | 9.7 |

| Sludge residue – top layer, (0–7 cm depth) | 110 |

| Sludge residue (7–14 cm depth) | 150 |

| Sludge residue (14–21 cm depth) | 80 |

In order to obtain good healthy vegetation and well-functioning STRB again, it is necessary to reduce the nickel concentration in the feed sludge either by the source or at the WWTP. In the specific case, the industry, which caused the nickel pollution in the wastewater, closed for a few years after 2011 and the vegetation was re-established.

19.4.3 Case 3: Treatment of Water Works Sludge

Treatment and disposal of coagulated settled water works sludge presents a great difficulty for the water industry in Europe [28]. In general, dewatering characteristics are poor and the sludge is of limited beneficial use.

Water works (WW) sludge is generated during the purification and filtration processes of low solid waters from freshwater reservoirs, lakes or rivers or from groundwater reservoirs. For the purification process, coagulants, such as aluminium sulphate or polyaluminium chloride, and Iron based coagulants, such as ferric sulphate or ferric chloride, are used for removing impurities, after which the sludge is thickened and dewatered.

The sludge quality may considerably vary from one work to another [28], but all tend to be:

- Sticky

- Difficult to handle

- Often have an unpleasant odor (dependent on their source).

In general, most dewatered sludge goes to landfill at considerable costs [28]. Alternatively, sludge is dewatered onsite or it is transported to the nearest Waste Water Treatment Plan (WWTP) for dewatering. The typical method for dewatering of water works sludge is by mechanical treatment systems. However, in the last decade full-scale STRBs and test systems have been introduced for sludge dewatering of water works sludge.

In the following sections, results are presented from sludge treatment in STRB of Water Works Sludge from Hanningfield and Whitacre Water Work, briefly described below (Table 19.4).

Table 19.4 Treatment of water works sludge in STRB systems in England.

| STRB | Period | No. of basins | Total basin area (m2) | Sludge type | Reference |

| Hanningfield WW STRB Test | 2008–2013 | 6 | 120 | Ferric sludge | [21, 29] |

| Hanningfield WW Full-scale STRB | 2012–2014 | 16 | 42,500 | Ferric sludge | [21, 29] |

| Lumley WW STRB Test | 2010 | 3 | 3 | Alum sludge | ARM/Orbicon |

| Whitacre WW STRB Test | 2015–2016 | 3 | 3 | Ferric sludge | ARM/Orbicon |

| Whitacre WW Full scale STRB | 2016–2018 | 4 | 1,475 | Ferric sludge | ARM/Orbicon |

WW + Water Works.

Hanningfield Water Works (Northumbrian Water, England)

Currently the world's largest full-scale STRB system of 4.5 hectares and 16 basins for treatment of water works sludge is from Hanningfield Water Works. Hanningfield STRB was constructed full-scale in 2012, representing a treatment capacity of 1,275 tons dry solid per year and is situated approximately 3 km from the water works (Figure 19.7; Table 19.4).

Figure 19.7 Hanningfield STRB system treating sludge from Hanningfield Water Works situated 3 km from the STRB (Photo: Orbicon September, 2012).

The sludge quality from Hanningfield Water Works was originally tested in an STRB test system in the period 2008–2013 [21, 29] before the full-scale system was established (Figure 19.8). A trial was set up with six basins each of 20 m2 at the Hanningfield Reservoir in Essex to examine the dewatering processes of the sludge produced at the water work. The test system was built with a design comparable to a full-scale plant with reeds, ventilation, sludge input; reject water systems as well as filters and drains.

Figure 19.8 Hanningfield test STRB (Photo: Orbicon 28.05.2011).

Whitacre Water Works (Severn Trent Water) and Test System

Whitacre Water Works (England) will by 2017 begin treating sludge by means of a full-scale STRB. Prior to the decision for a full-scale STRB, ferric sludge from Whitacre Water Works was tested in an STRB test system in a five-month period in 2015, with the purpose to clarify whether the sludge was suitable for treatment in a STRB. The Whitacre STRB pretest system was built with three basins each of 1 m2 filter area with a design comparable to a full-scale plant with reeds, ventilation, sludge input, filtrate water systems as well as filters and drains. One container (IBC) was used for sludge holding before loading.

Whitacre Water Treatment Works generates sludge waste primarily from the de-sludging of the pulsator clarifiers producing primarily mineral ferric sludge and sludge from washing of the clarifiers. The existing treatment comprises coagulation with ferric sulphate.

19.4.3.1 Feed Sludge and Resulting Filtrate Quality

The feed sludge quality from WW are in general characterized by a low dry solid content and a high iron or aluminium content, due to the production process at the works using ferric- or aluminium sulphate/chloride for the coagulation process.

WW sludge is characterized by a much lower dry solid content (0.1–0.2% ds), five to ten times lower than typical activated sludge from WWTP. Moreover, the level of organic material and fats and oil is generally low in WW sludge (<1000 mg/kg ds) as the sludge is generated from a production process involving mainly surface water or groundwater. Based on experience, these parameters do not cause operational problems.

Dry solid content in feed sludge from Whitacre and Hanningfield WWs were in the range 0.1–0.5% ds (Figure 19.9) and for suspended solids in the range of 100–8,000 mg/L (Table 19.5). The data show that there is a large variation in the total solids loaded onto the basins (Figure 19.9). Therefore, it is very important to know the percentage of dry solids in each load in order to calculate the load (kg ds/m2/yr) as precisely as possible. If an average “total solids” value is used to calculate the load, there is a risk that the load may be overestimated in some basins and underestimated in others.

Figure 19.9 Total solid (%) in feed sludge at Hanningfield WW in the period from 2008–June 2013.

Table 19.5 Feed sludge quality parameters for Whitacre (Test) and Hanningfield (Test and Full-scale) WWs. Both works use ferric sulphate for the coagulation process.

| Feed sludge from WW | Whiteacre | Hanningfield | Interval range (both WW) | |

| Sampling STRB site: | Test STRB | Test/Full-scale | ||

| Sampling period: | Autumn 2015 | 2008–2013 | ||

| Parameter | Unit | Average (n = 2) | Average (n > 25) | (n > 25) |

| Dry solids | % | 0.3 | 0.2 | 0.1–0.5 |

| Suspended solids | mg/L | 2,630 | 1,262 | 100–8,000 |

| Loss on Ignition | % | 40 | 23 | 10–40 |

| pH | – | 7.3 | 7.4 | 6.8 – 8.7 |

| Fat and oil | mg/kg ds | 604 | 10–2400 | |

| Iron (total) as Fe | mg/kg ds | 258,530 | 232,800 | 100,000–400,000 |

| Aluminum total | mg/kg ds | 432 | 408 | 100–3,000 |

| Total nitrogen | mg/kg ds | 2,300 | 1,000–14,000 | |

| Total phosphorous | mg/kg ds | 6964 | 1,500–11,000 | |

| Phosphate as P | mg/kg ds | 7,241 | 2,000–8,000 | |

| Chloride | mg/kg ds | 16,301 | 41,568 | 15,000–45,000 |

| Calcium, total | mg/kg ds | 33,555 | 98,143 | 32,000–290,000 |

The sludge from the two WWs was characterized by relatively low contents of organic material (as determined by LOI) between 20–40% of dry solids (Table 19.5). Sewage sludge usually has organic contents of approximately 50–70% determined by LOI.

The fats and oil content for Hanningfield WW was very low (on average 600 mg/kg ds, ranging from 10–2,400 mg/kg ds). The feed sludge had a high iron content around 250,000 mg/kg ds, ranging from 100,000 up to 400,000 mg/kg ds. The pH level is within the limits to allow good growing conditions for the reeds. There is nitrogen and phosphorus in the sludge, which makes it possible to reduce or even avoid fertilizer additions. After drainage the resulting filtrate water quality shows significant reductions in dry solids (70%), suspended solids (>95%), iron content (>95%) and total phosphorous (>95%) (Table 19.6).

Table 19.6 Filtrate water quality parameters after treatment in a STRB at Whitacre and Hanningfield WW.

| Filtrate water | ||||

| from WW | Whiteacre | Hanningfield | Data range | |

| Sampling site: | Test STRB | Test/Full-scale | ||

| Sampling period: | Autumn 2015 | 2008-2013 | ||

| Parameter | Unit | Average (n = 3) | Average (n > 25) | |

| Dry solids | % | 0.06 | 0.05 | 0.001–0.06 |

| Suspended solids | mg/L | 93 | 0.01 | 0.001–0.05 |

| pH | 7.9 | 7.7 | 7.0-8.0 | |

| BOD5 | mg/L | 5 | 2.4 | 1–36 |

| COD total | mg/L | 44 | 33 | 3–380 |

| Iron (total) as Fe | mg/L | 29 | 4.5 | 0–120 |

| Total phosphorous as P | mg/L | 0.1 | 0.2 | 0–4.6 |

| Total nitrogen as N | mg/L | 3.3 | 0–10 | |

| Chloride | mg/L | 52 | 74 | 50–100 |

19.4.3.2 Sedimentation and Capillary Suction Time

A sedimentation test of sludge is simple and quick first indication of the dewater ability of the feed sludge. Due to the usually low fat and oil, content in WW sludge, the sedimentation of suspended material proceeds rather fast, as shown in Figure 19.10 from Hanningfield STRB. The sludge settled to approximately 8 to 10 cm within 30 minutes. The filtrate water (above the settled sludge phase) is transparent without any coloring (Figure 19.10). As the sludge sedimentation characteristics may change over time due to upstream changes at the WW, it is recommended to measure the sedimentation repeatedly during a test period.

Another simple but good indication of the sludge dewater ability is the capillary suction time (CST). The CST is a measure of the dewatering properties of sludge. This method is essentially measuring how quickly the sludge wets a filter paper. A good dewatering ability corresponds to a CST range of 10–100 seconds (Figure 19.11).

Figure 19.10 Sedimentation of Hanningfield WW sludge performed on sludge sampled 28.07.2009 (Photo: Orbicon).

Figure 19.11 Capillary suction time (CST): measurement of surplus activated sludge and water works sludge. Red dots indicate Hanningfield WW and blue dots Whitacre WW.

The values of CST measured for WW sludge are in the higher end of what normally is observed for WWTP sewage sludge, which indicates that the sludge is somewhat more difficult to dewater. However, the higher CST values of the WW sludge did not affect the dewatering and the cracking of the sludge.

The capillary suction time (CST) of Hanningfield nd Whitacre WWs were both approximately 2–4 times (30–110 sec) the suction time in surplus activated sludge (10–40 sec). However, there are examples of digested sludge from WWTP with CST values of more than 1,000–2,000 sec. These types usually have a high content of fat and oil.

19.4.3.3 Sludge Volume Reduction and Sludge Residue Development

After a load of sludge, the dewatering phase results in the dry solid content of the sludge remaining on the filter surface as sludge residue, whereas the majority of its water content continues to flow vertically through the sludge residue. The water content is further reduced through evapotranspiration. The volume reduction is typically very high due to the low dry solid content in the sludge.

During the 5.5 months loading period in the Whitacre STRB test, there was a volume reduction of 97–98%. In the intensive loading periods with four days of loading, e.g., in basin 3 from 23rd–27th November, the sludge residue height increased fast, whereas the height was markedly reduced during the following resting period due to dewatering and evapotranspiration (Figure 19.12).

Figure 19.12 Whitacre STRB Test. Basin nos 1–3. Sludge residue height (cm) during the test period July–December 2015. Red arrows show the increase and decrease in sludge residue height during the load and subsequent resting period.

In the Hanningfield test STRB, the sludge volume reduction after 3–5 days of loading was of the same magnitude (>98%). In full-scale systems with much longer resting periods than in the test, the reduction is even more pronounced. The general experience from treatment of WW sludge in both test and full-scale systems is that the dry solid content (approx. 0.1–0.2%) in the feed sludge is concentrated 100–200 times to a dry solid content in the sludge residue of between >25% up to 40% ds [30]. In Hanningfield, dry solid contents of even above 50% ds in the sludge residue were obtained in some of the test basins.

The (visual) development of the sludge residue surface after loading and during the resting period is a very important indication of the dewater ability of the sludge. After a sludge load, the WW sludge typically cracks up quickly (Figures 19.13 and 19.14). A main reason for this is the low content of fat and oil and organic matter in WW sludge. For comparison, some types of sewage sludge – especially sludge originating from treatment of wastewater with a large proportion of dairy or abattoir wastewater (fat and oil) – will not crack up.

Figure 19.13 Examples of the sludge surface n Whitacre Test system. Pictures are taken 21 days after the last load (left) and 1 day after the load (right). Note the evident cracks in the sludge after only 1 days' rest (Photo: Orbicon, reproduced with permission).

Figure 19.14 Sludge residue in the Lagoon at Whitacre WW showing that the sludge residue is cracking up. (Photo: Orbicon, 13.08.2015, reproduced with permission.)

19.4.3.4 Filtrate Water Flow

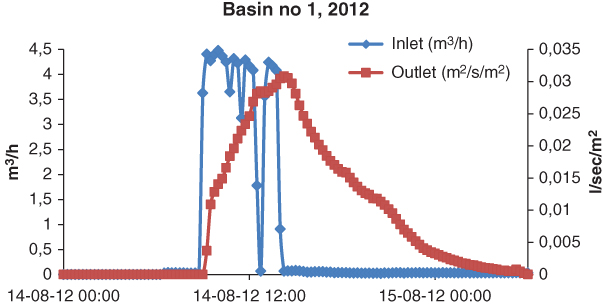

The majority of the water in a sludge load continues to flow vertically through the sludge residue and filter to the drainage system. In general, the filtrate flow curve is one of the most important parameters to follow in the operation of an STRB (Figure 19.15). If the flow peak (L/sec/m2) decreases over time after each resting period or if the flow curve tail does not decline to zero in the initial part of the rest period, this indicates that the STRB basin does not work as intended.

Figure 19.15 Hanningfield test STRB: four loads on the same day (blue curve, m3/h) on test basin no. 1 and the resulting dewatering profile (red curve, L/sec/m2), year 2012.

The filtrate water curves from Whitacre and Hanningfield test systems resembled filtrate water curves normally seen in full-scale systems for normal sewage sludge with an initial top, which then declines towards zero flow within few hours (Figure 19.15). The maximum flow rate was typically between 0.015–0.03 L/sec/m2. The dewatering (L/sec/m2) in the Hanningfield full-scale and test system has generally been good with no observed occurrences of surface clogging, slow dewatering or water ponding/no drainage through the sludge residue. The quality of the filtrate water strongly indicated that there is no bypass of sludge in the test basins.

Hanningfield: In some basins the maximum dewatering speed was over 0.025 L/sec/m2, approximately two times higher than that seen from well-functioning STRB systems treating sludge from WWTP [30].

In summary the overall results from full-scale STRBs and test systems treating WW sludge has shown that WW sludge is treatable in an STRB system provided these systems are built and operated correctly and that the sludge quality is of the “normal” WW type.

19.5 Discussion and Conclusions

The sludge quality highly influences the dewater ability of sludge. STRBs are generally robust systems, which have been shown able to dewater many sludge types. Because mineralization takes place during the long treatment time in an STRB, the method has an advantage compared to traditional mechanical solutions. For example, STRBs reduce and degrade hazardous organic compounds effectively in contrast to mechanical solutions, where organic pollutants are not degraded [8].

19.5.1 Industrial Sludge

In general, higher concentrations of organic solids result in a lower dry solid percentage and more pronounced anaerobic conditions in the sludge residue. The level of fats and oil, together with the organic content and heavy metals, are main parameters to focus on and test for in industrial sludge. If the sludge quality contains high levels of fats and oil, it is important to address this upstream the STRB at the WWTP, e.g., by improving fat and grease removal and by reducing the content in the incoming wastewater to the WWTP.

Before investing in a full-scale STRB system, it is often advisable as a first step to establish STRB test systems to assess the sludge treatability in an STRB system. A thorough test in a test STRB provides valuable information about (1) if the sludge can be treated in an STRB; (2) the dimension criteria of a full-scale system, e.g., the areal load (kg ds/m2/yr) and the number of basins.

Unlike organic compounds, heavy metals are not degraded in an STRB system, but are mainly bound in the sludge residue and filter. Heavy metal concentrations may be originated in wastewater from the industry, e.g., abattoirs constitute a larger proportion, than in normal wastewater. During the sludge treatment period in STRB, the concentrations of heavy metal may increase in the oldest layers because of the mineralization of organic solids (up to 20–25%) [22]. In some cases, i.e., in the oldest layer, it may exceed the legal national standards (Danish standards, BEK. No. 1650 of 13/12/2006) for soil application when expressed as “mg/kg ds” [15].

However, as shown by Nielsen and Bruun [22], the quality of the sludge residue in general, and even for sludge residues older than 20 years, complies with the EU and Danish regulations (BEK No. 1650 of 13/12/2006), when based on the contents of heavy metals in relation to phosphorus [22].

19.5.2 Water Works Sludge

Regarding WW sludge, the overall results from full-scale STRBs and test systems showed that WW sludge is treatable in an STRB system, provided these systems are built and operated correctly and that the sludge quality from the WW are of the “normal type” (low contents of organic material, and fat).

The sludge treatment results from Hanningfield and Whitacre WWs STRBs has shown that reeds were not inhibited by WWs sludge (e.g., high ferric) as the reeds grew well and in good health in both full-scale and test system. In summary:

- The dewatering was good. Shortly after the water has drained out of the system, the sludge residue surface cracks up very well. Even after 24–25 loading days in a row, the sludge cracks up after a few days' rest.

- The area load during the tests corresponded to between 30–45 kg ds/m2/yr.

- The ferric sludge was dewatered to approximately 40% dry solids and desiccates in the trial beds.

- Filtrate water flow from the basins was good and had a curve with maximum flow of 0,02–0,03 L/m2/sec shortly after loading, which then rapidly declined during following hours.

- Iron: There was no indication of iron in the filter layers and the concentration in the reject water was low during the 5 years of test operation. This indicates that the iron stays in the sludge residue and does not clog the drainpipes.

- Due to the high iron content caused by the production process at the works using ferric sulphate (Hanningfield) for the coagulation process, it is extra important to have aerobic conditions in the sludge residue in order to avoid iron precipitation as ochre in the filter and drain. Ochre might then clog the filter.

- Vegetation: The reeds in both tests (Hanningfield and Whitacre) showed in general to have been in good health during the whole test period and the feed sludge had no negative effect on the reed growth.

In summary, the sludge treatment results obtained from Hanningfield and Whitacre WWs in full-scale and test STRB systems showed that these were able to dewater the sludge satisfactorily.

Acknowledgements

The authors want to thank the technical staff at the Waste Water Treatment Plants and the Water Works for their technical assistance during operations and sampling. Data and results from the STRB test systems treating water works sludge have been obtained in collaboration between Essex and Suffolk Water, ARM Ltd and Orbicon A/S.

References

- 1 Mantovi P, Baldoni G, Toderi G. Reuse of liquid, dewatered, and composted sewage sludge on agricultural land: effects of long-term application on soil and crop. Water Res. 2005; 39(2):289–296.

- 2 Harrison EZ, Oakes SR, Hysell M, Hay A. Organic chemicals in sewage sludges. Sci Total Environ. 2006; 367(2):481–497.

- 3 Fytili D, Zabaniotou A. Utilization of sewage sludge in EU application of old and new methods – a review. Renew Sust Energ Rev. 2008; 12(1):116–140.

- 4 Salado R, Vencovsky D, Daly E, Zamparutti T, Palfrey R. Environmental, economic and social impacts of the use of sewage sludge on land. Part II: Report on Options and Impacts, 2010. Report by RPA, Milieu Ltd and WRc for the European Commission, DG Environment.

- 5 Nielsen S, Willoughby N. Sludge treatment and drying reed bed systems in Denmark. Water Environ J. 2005; 19(4):296–305.

- 6 Uggetti E, Ferrer I, Llorens E, Garcia J. Sludge treatment wetlands: a review on the state of the art. Bioresour Technol. 2010; 101:2905–2912.

- 7 Nielsen S. Assessment of sludge quality for treatment in sludge treatment reed bed system – trial systems. Water Sci Technol. 2016; (in press).

- 8 Nielsen S. Economic assessment of sludge handling and environmental impact of sludge treatment in a reed bed system. Water Sci Technol. 2015; 71(9):1286–1292.

- 9 Nielsen S. Mineralisation of hazardous organic compounds in a sludge reed bed and sludge storage. Water Sci Technol. 2005; 51(9):109–117.

- 10 Nielsen S. Sludge treatment and drying reed bed systems. Wastewater treatment in wetlands: theoretical and practical aspects. Water Sci Technol. 2007; 3–4:223–234.

- 11 Nielsen S, Peruzzi E, Macci C, Doni S, Masciandaro G. Stabilisation and mineralisation of sludge in reed bed systems after 10–20 years of operation. Water Sci Technol. 2014; 69(3):539–545.

- 12 Peruzzi E, Nielsen S, Macci C, Doni S, Iannelli R, Chiarugi M, Masciandaro G. Organic matter stabilization in reed bed systems: Danish and Italian examples. Water Sci Technol. 2013; 68(8):1888–1894.

- 13 Nielsen S. Sludge drying reed beds. Water Sci Technol. 2003; 48(5):101–110.

- 14 Nielsen S. Helsinge sludge reed bed system: reduction of pathogenic microorganisms. Water Sci Technol. 2007; 56(3):175–182.

- 15 Matamoros V, Nguyen LX, Arias CA, Nielsen S, Laugen MM, Brix H. Musk fragrances, DEHP and heavy metals in a 20 years old sludge treatment reed bed system. Water Res. 2012; 46(12):3889–3896.

- 16 Siracusa G, La Rosa AD. Design of a constructed wetland for wastewater treatment in a Sicilian town and environmental evaluation using the emergy analysis. Ecol Model. 2006; 197(3):490–497.

- 17 Zhou JB, Jiang MM, Chen B, Chen GQ. Emergy evaluations for constructed wetland and conventional wastewater treatments. Commun Nonlinear Sci Numer Simul. 2009; 14(4):1781–1789.

- 18 Dixon A, Simon M, Burkitt T. Assessing the environmental impact of two options for small-scale wastewater treatment: comparing a reedbed and an aerated biological filter using a life cycle approach. Ecol Eng. 2003; 20(4):297–308.

- 19 Olsson L, Larsen JD, Ye S, Brix H. Emissions of CO2 and CH4 from sludge treatment reed beds depend on system management and sludge loading. J Environ Manage. 2014; 141:51–60.

- 20 Kopp J, Dichtl N. Prediction of full-scale dewatering results by determining the water distribution of sewage sludges. Water Sci Technol. 2000; 42(9):141–149.

- 21 Nielsen, S. Sludge treatment reed bed facilities-organic load and operation problems. Water Sci Technol. 2011; 63(5):942–948.

- 22 Nielsen S, Bruun EW. Sludge quality after 10–20 years of treatment in reed bed systems. Environ Sci Pollut Res. 2015; 22(17):12885–12891.

- 23 Kołecka K, Nielsen S, Obarska-Pempkowiak H. The speciation of selected heavy metals of sewage sludge stabilized in reed basins. 11th International IWA Specialist Group Conference on Wetland Systems for Water Pollution Control 1–7, 2008. Indore, India.

- 24 Stefanakis AI, Tsihrintzis VA. Heavy metal fate in pilot-scale sludge drying reed beds under various design and operation conditions. J Hazard Mater. 2012; 213:393–405.

- 25 Kołecka K, Obarska-Pempkowiak J. Potential fertilizing properties of sewage sludge treated in the sludge treatment reed beds (STRB). Water Sci Technol. 2013; 68(6):1412–1418.

- 26 Federle TW, Itrich NR. Comprehensive approach for assessing the kinetics of primary and ultimate biodegradation of chemicals in activated sludge: application to linear alkylbenzene sulfonate. Environ Sci Technol. 1997; 31(4):1178–1184.

- 27 Allen SE.,. Chemical Analysis of Ecological Material, 2nd edn. Blackwell Scientific Publications, Oxford, 1989, 368 pp.

- 28 Nielsen S, Sellers TCP. Paper and presentation: Dewatering sludge originating in water treatment works in reed bed systems – 5 years of experience. 17th European Biosolids and Organic residuals Conference and Exibition, 2012. Leeds, UK.

- 29 Nielsen S. Sludge treatment in reed beds systems – development, design, experiences. Sustain Sanit Pract. 2012; 12:33–39.

- 30 Nielsen S, Cooper DJ. Dewatering sludge originating in water treatment works in reed bed systems. Water Sci Technol. 2011; 64(2):361–366.