5

WHAT? DEVELOPING BUSINESS ARCHITECTURE

THE DIGITAL AGE demands new skills: companies that want to be successful in their industries and the emerging ecosystems must get their functions and processes in shape for the new era.

What do successful digital companies have in common? They all base their products and processes strictly on the needs of the customer, which is why this chapter on the development of the business architecture starts with the customer experience. We describe how a shopping or service experience can be orchestrated across numerous channels, we identify the opportunities of automated pricing, and we dive into the world of social media, which has revolutionized marketing.

We then move on to the product and its value proposition. In keeping with the new digital philosophy, products are no longer launched in perfect condition, but come to market in their basic configuration, and are then rigorously further developed. Real-time customer reactions are incorporated into the ongoing development, and the products and services approach perfection in iterative loops.

The value chain also faces sweeping changes as the Internet of Things, robots, and artificial intelligence revolutionize production, the supply chain, and administration. To link robots, machines in production, and the supply chain, connectivity is needed as well as technical platforms that interact with sensors and actuators.

5.1 OMNICHANNEL: A PRESENCE ACROSS ALL CHANNELS

Lareina Yee and Martin Harrysson describe how companies leverage all sales and communication channels to the maximum.

Iron and steel are very traditional industries. Yet in the digital age, even heavy industries are now treading new paths in sales and distribution. The Chinese iron and steel group Baosteel offers its entire product range, from sheet steel to specialist aluminum products, via its online platform Ouyeel. Customers are able to find all the information they need on the user-friendly site in a single click. The steel manufacturer has digitized its entire ordering and delivery process, while also offering other services on the platform such as financing.

Baosteel demonstrates the concept of omnichannel, where customer sales and customer contact occur across all channels. It is no longer limited to classic retail and its end consumers. It has now spread to all industries, from banking, insurance, and energy utilities right through to purely B2B industries. In all cases, it’s clear that digitization is fundamentally changing not only how customers find information and make purchases, but also how companies and their existing and potential customers communicate and interact.

Omnichannel Is Both a Challenge and Opportunity for All Industries

Until just a few years ago, some transactions in banking and insurance were conducted via one channel only for regulatory reasons. People who wanted to open a bank account or take out an insurance policy had to complete at least the final step offline, and legally verify their identity in the bank branch, at the insurance agency, or at the post office. With digital verification methods, even these final steps can now be performed across multiple channels. Start-ups like Socure, WebID, and The ID Co. now offer identity verification processes via video or smartphone, thus digitizing the final step to opening an account or taking out a policy even in this complex regulatory environment.

Travel and hospitality service providers not only are working intensively on digitizing their customer contact processes, but also face immense competition from digital intermediaries and platforms like Priceline and Expedia, which are investing huge sums in marketing, in an effort to gain direct customer access.

And as our opening example shows, the digitization of customer contact has even become commonplace in B2B sectors like heavy industry. While Baosteel operates its own platform, its rivals sell their steel by the ton on Alibaba. Chemicals group BASF also sells its chemicals to Chinese small and midsize enterprises (SMEs) via Alibaba.

The multichannel approach not only is used to inform customers and sell products, but also offers a direct link to the company. Insurers, for example, have opened up the digital channel to enable car drivers to submit damage reports with a photo from their smartphones. Health insurance customers can scan their medical receipts with an app and submit claims for reimbursement. It’s no coincidence that one of the top priorities of Allianz is the radical digitization of all relevant customer contact points.

In Five Years, the Millennials Will Be the Strongest Consumer Group

The pioneers of development are the retailers and service providers that have contact with the end customers. They are now preparing for a generation of customers who grew up in the digital age. In five years, people born after 1990 will be the strongest consumer group. According to a survey, 77 percent of this generation spends three or more hours online each day; for 56 percent, their smartphones are their most important shopping tool, and even though they have a lower income on average than the general population, they are above-average spenders online.

Brick-and-mortar retail has responded to the needs of young people with an omnichannel strategy, providing offers across all sales channels. This is also known as a multichannel strategy or 360-degree commerce. In implementing such a strategy, the company must decide in which sales channels, on which platforms, and at which contact points it wants to be visible to its customers, and how to interact with them. Customers today want to be free to decide which channels they use to find information, to make purchases, and to receive their goods or services. They want to be able to move seamlessly between these channels and contact points.

In the early years, the online activities of main-street retailers were predominantly defensive—to ward off their online competitors. Today, the established retailers display their full strengths. They use their stores as a customer contact weapon where customers can physically experience the goods, receive advice, and even collect or exchange goods that they ordered online. They’ve done it so successfully that online-only retailers are starting to think multichannel. Amazon is now opening physical stores and collection points where ordered goods can be collected. This shows that even the new digital retailers mustn’t underestimate the old brick-and-mortar model. At the beginning of 2016, a good 90 percent of all retail revenues were still generated offline.

Strategy and Implementation: Structure Is Everything

In many industries that deal with the end customer, digital measures have only led to a set of further sales and marketing channels—online, mobile devices, social media, and chat forums. In many cases, this has simply exacerbated the classic channel conflicts, with the managers of the respective sales channels competing more against their colleagues rather than against the competition. To ensure this doesn’t happen, it’s worth bearing in mind some fundamental rules.

Set the Right Targets

The aim is simple: companies need to offer their customers a consistent experience across all channels and across all contact points. But what does this actually mean? In retail, for example, it includes services and offers, such as customers being able to check on a smartphone whether an item they saw in a commercial is available in the nearest store. Or perhaps targeting customers who are browsing in a store with vouchers or discount coupons sent to their smartphone. For electricity and gas customers, it means addressing them by name when they visit the website and log in. Banks have integrated their services in such a way that customers can start filling out a loan application on their smartphone before going to bed at night, and then complete it in their branch the next day on their lunch break and sign the contract.

For companies, work starts with the strategic issue of which channel mix is best for the target customers. What roles do the individual channels and platforms play, and how can they be integrated into a true multichannel offering? The question as to which channels a company doesn’t want to include in its strategy is also implicit: does an energy utility need to be present on price-comparison sites, thus starting a price war?

These questions can be answered only if managers precisely understand the needs of their target customers. To do so, they need to understand the customer decision journey from initial contact with an offer in a shop window or on the website, through the research phase and the consideration phase, to the actual order and potential after-sales services. This journey differs vastly from customer to customer, which makes it even more important to ensure customers are able to switch seamlessly between channels. “The art of selling is the same across all channels,” according to Andy Street, head of marketing at successful British multichannel retailer John Lewis, “which is why we need to ensure that customers don’t have to worry about which channel they’re currently using because they get the same offer presented in the same way on whichever channel they choose.”

Keys to Success: Data

To fully understand the customer journey through the various channels, companies rely on data. Modern market researchers, or customer insight specialists, leverage customer satisfaction data at all contact points. Data scientists then study where potential customers exit the journey, and use this data to identify where friction and dissatisfaction exist. The results are then presented to management, which looks at ways to bridge these shortcomings. And since today’s customer needs and habits change dynamically, data analysis is not a one-off process, but must be a constant cycle of measuring, analyzing, and optimizing.

Keys to Success: Organization and Culture

Optimizing the customer experience at the various touch points can succeed only if the optimizer consistently thinks from the customer perspective, which requires the committed abolition of company silos and departmental thinking. However, this can happen only if the sales channels are not managed individually in separate organizational units. And yet this is still the reality in many companies, which have grown with the new channels, setting the ideal prerequisites for serious channel conflicts. The only remedy is to think like the customers, and trace their journey through the contact points with a cross-departmental and cross-functional mind-set.

Customer-centric thinking is a key marker of digital organizations for most companies. However, it requires cultural change and the willingness to test and learn. Whenever new channels or contact points emerge, companies should use them to approach customers. If the response is positive, the channel can be expanded; if it’s negative, the company can make a quick exit. Nevertheless, companies must be constantly willing to innovate, and be prepared to accept failure.

U.S. fashion chain Nordstrom, for example, established its own cross-functional teams in an “innovation lab” to conduct these quick tests. British retailer John Lewis constantly trials new technologies in its stores. Most recently it tested smart mirrors; a customer clicked on an item of clothing, which the integrated computers then portrayed as a virtual and 3D image superimposed onto the customer. If customers liked what they saw, they could scan the QR code and place the item in a digital shopping basket. John Lewis then sent the customer the mirror image by e-mail as a service. “Great fun and an excellent idea” was how the project team summed up the trial—and then promptly terminated it. Although the idea was a popular gimmick among customers at first, it failed to produce any new findings on customer behavior or increased sales.

Keys to Success: Technology

To be successful across all channels, companies need to rethink their technology. It should no longer be seen as just a support function, but must instead be developed into a core competency.

To support customers through all touch points, data must be collected at each point and aggregated in the background. Not only does this require extremely powerful databases, which are increasingly based in the cloud, but also integrated IT systems. Once in place, software is needed to analyze the aggregated data. Only once a company has identified whether customers leave its online store after just a few minutes of browsing without buying anything, or leave after viewing products and possibly placing a product in the shopping cart, will it know whether it needs to improve the offering, the loading times of the pages, or the buying process.

Only companies that employ analytics software that can show where an ordered product is in the supply chain at any given time—in the warehouse, in the sorting center, or already in the delivery van—can offer their customers services like “track and trace.” The website, especially the version for mobile versions, must be continuously optimized with new features. A home page that crashes due to overloading means lost revenue.

However, upgrading the technology means investment. U.S. home improvement chain Home Depot, for example, announced plans to invest around 40 percent of its overall investment budget in technology and IT over the next three years.

Amazon, too, the pioneer of online retailing, has long operated across numerous channels, and is continuously testing new ideas—such as the supermarket of tomorrow, which it launched as Amazon Go. Its grocery store customers check in on a smartphone, are greeted personally, and then are directed to products that may be of interest, either because they have bought them before or because they’re reduced in price. The smartphone points the way to the relevant shelf, the customer scans the codes of his or her purchases, and drives home—no lines, no checkout. Payment is made with the credit card associated with the app, just like online shopping, and the receipt is e-mailed to the customer.

5.2 DYNAMIC PRICING: UP-TO-THE-MINUTE PRICES

Ramji Sundararajan on dynamic pricing, and why two people can pay vastly differing sums for the same product, from the same provider.

A typical online fashion retailer has a range of seven million items, while the major multicategory providers like Amazon have much more. In addition, the most successful online retailers change their prices for the individual items every 15 minutes. How is this possible? If you’re now trying to calculate how many employees are required to work tirelessly in their offices analyzing price elasticity trends and how these affect individual prices, you’re on the wrong track. Dynamic pricing is fully automatic, with computers taking over the work of calculating and processing huge volumes of data about competitors’ prices, sales promotion figures, potential customers’ search trends, product ratings on Internet forums, and even comments on Twitter and Facebook. Depending on the company’s strategic aims, whether it’s maximizing market share or profit, an algorithm calculates the optimal price when necessary, sometimes refreshing every minute.

Dynamic pricing, which was introduced in 2005 by Amazon and others, saves the margins of online retailers because online shoppers have become shrewd bargain hunters. Price-comparison websites and ratings communities have enabled the sort of transparency that never existed before, and aggressive new retailers often explode existing price structures with cheap introductory offers. Dynamic pricing plays a crucial role in boosting both consumer price perception and retailer profitability. Typically, dynamic pricing can unlock a 3 to 8 percent return on sales rapidly and is a huge competitive advantage.

Retailers retaliate with two different versions of dynamic pricing: One version optimizes prices for an entire range, which apply to all customers across the board. This is ideal for products that are easy to compare, such as brand items. The second version calculates a tailored price for each customer individually. This works better when direct comparisons are more difficult such as with insurance products or travel.

Algorithms Find the Best Prices

Luckily for retailers, the best price is not always cheaper than competitors’ prices. As experiences in local retail have also shown, customers form an opinion on whether a store offers good value for money or is expensive based on relatively few prices for specific products. In supermarkets, for example, impressions are generally formed on frequently purchased items like milk, butter, and detergent, which is why retailers choose these products for their aggressive special offers.

And it’s no different online. The important thing is to know the products on which customers base their opinions about value for money. Once again, the best example is Amazon: The e-commerce giant defines key value items throughout each of its categories, which it consistently offers at lower prices than its major competitors. In the case of ink cartridges for printers, for example, Amazon knows that most buyers first look at the price of a twin pack of black ink. In 2016, Amazon undercut its two strongest competitors for this product by more than 20 percent. However, when it came to the single pack of black ink, which is also a frequent buy, Amazon was only just under its competitors. Yet these low prices are more than compensated by the prices for colored ink: yellow, blue, and red are between 33 percent and 57 percent more expensive than at Amazon’s competitors.

The great thing about digital pricing is that the company is constantly learning. Computer programs track the responses of customers and competitors to a new price in real time: Are sales moving as planned? How many people showing an interest fail to make a purchase? Where do the new customers come from—price-comparison sites, websites of competitors—or did they come to our website specifically? All the findings are immediately entered into the pricing model, which constantly updates and adjusts.

Companies that optimize their prices based on this formula even do away with the old 80/20 rule according to which 20 percent of products actually account for 80 percent of revenue and profit. Take the example of Amazon with cell phones: Around 80 percent of its revenue is made from selling devices that account for around 20 percent of its business in this category. The remaining 80 percent of items comprise accessories like chargers, connection cables, headphones, and smartphone cases. Although they account for only 20 percent of revenue, they still deliver 50 percent of profit. These are typical long-tail products. They remain in the assortment for years, long after the corresponding cell phone has been surpassed by newer models but is still used. In main-street stores, it isn’t cost-effective to continue stocking such a vast array of accessories, because the retail space is just too expensive. However, online retailers with their enormous and cheap warehouses can healthily boost their margins with these very items.

All the major online retailers have now established dynamic pricing systems, and the idea is also coming to brick-and-mortar retail. The U.S. retail chains Sears and Home Depot, for example, are now able to vary their in-store prices at the push of a button after installing electronic price labels in some sections within their stores. Once electronic price labeling has been established across the board, this opens up dynamic pricing opportunities even for multichannel retailers who started off in the physical space. Ultimately, today’s customers expect a consistent offering across all channels, even when it comes to prices.

Individually Tailored Prices

Tailored pricing goes one step further. In this case, the retailer attempts to classify the individual customer—for example, by analyzing which device was used to reach the website. If an expensive iPad was used, the system immediately shows a higher price than is displayed to a different customer using a cheaper product running the Android operating system. A cheaper offer is also shown to customers who have been redirected to the provider’s website from a price-comparison site. For a long time, systems have noted whether someone has previously visited the website and shown an interest in an offer. If the customer views the same item again on the website, the system forces a decision by promising a discount for an immediate purchase or offering free add-on services.

Once customers see through these pricing strategies, they are often less than amused, which is why many travel operators have given up differentiating customers according to the devices they use. Too many customers vented their frustration at being shown a higher price following a quick browse on their expensive iPhone than they were shown later at home on their old PC. However, price differentiation according to the route taken to the website is still very much in force among the core players in the travel industry.

The concept of tailored pricing is an area of interest for companies in many industries. Insurers are working on ways to better price individual risks, while energy companies want to incorporate individual consumption habits into their offers. And it’s not just in the retail space where dynamic pricing is winning out—the enterprise space is also experimenting with the concept, for example in the chemicals and steel industries. Steel distributor Baosteel’s online marketplace Ouyeel has created the kind of price transparency that never before existed in the industry. And BASF now trades on Chinese retail platform Alibaba, selling chemicals to thousands of predominantly SME clients in Asia.

Five Modules of Dynamic Pricing

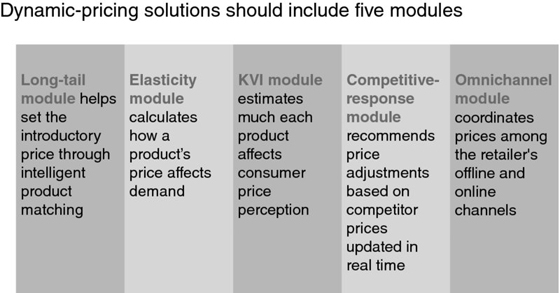

Dynamic pricing plays a crucial role in boosting both consumer price perception and retailer profitability. A robust dynamic-pricing solution should consist of five modules, all working in parallel to generate price recommendations for every SKU in the assortment:

- The long-tail module helps a retailer set the introductory price for new or long-tail items through intelligent product matching. The module determines which data-rich products are comparable to new items (which have no history) or long-tail items (which have limited historical data).

- The elasticity module uses time-series methods and big data analytics to calculate how a product’s price affects demand, accounting for a wide variety of factors, including seasonality, cannibalization, and competitive moves.

- The key value items (KVIs) module estimates how much each product affects consumer price perception, using actual market data rather than consumer surveys. This enables the module to automatically detect changes as to which items consumers perceive as KVIs.

- The competitive-response module recommends price adjustments based on competitor prices updated in real time.

- The omnichannel module coordinates prices among the retailer’s offline and online channels.

While a best-in-class solution includes all five modules, companies can often begin with only the KVI and competitive-response modules. These help companies nimbly respond to competitive moves on key items, while they add the rest of the modules over time.

Companies looking to lay the groundwork for a functioning dynamic pricing system know it can be done—and the effort is worth it. Some e-commerce retailers have achieved margin gains of two to three percentage points—and in an industry that operates with such tight margins, that can make the difference between being an industry leader and a follower.

And with results like that, concepts soon catch on. In the next few years, dynamic pricing is likely to become a core competency in business. The next wave will affect the B2B sector, where prices in many industries still lack transparency. Such new openness could trigger shock waves. Just think of the current practices in industries like steel or chemicals. In the B2C sector, the trend is increasingly moving toward more customized offerings, including tailored prices.

The big question is whether customers will rebel. Just because something is technically feasible doesn’t mean it will be accepted, as the example from the travel industry shows, where companies had to give up price differentiation based on whether a customer was using an expensive Apple product or a cheap no-name PC. However, there are other options for setting tailored prices, and they will pose an interesting challenge for creative companies.

5.3 DIGITAL MARKETING: TAILORED MESSAGES ACROSS ALL CHANNELS

Brian Gregg on why content is king in digital marketing, and how companies can master the discipline.

On average, people look at their cell phones 200 times a day to check for messages. A 20-year-old today has already received 20 million marketing messages during his or her young life. In the 1990s, this figure would have been only a million. Adult U.S. citizens spend just under six hours online each day, and it’s not much less in Europe. In the United States, Google generates more advertising revenue than all the country’s daily newspapers put together.

We chat, we tweet, we text, we e-mail, we post photos to Instagram, and we watch videos on YouTube anytime, anywhere. Our use of media has changed radically. And just as radical are the upheavals in marketing. As conventional advertising reaches ever-dwindling numbers of the younger generation, so continuous measures to build brand awareness and trust online become more important.

The established marketing companies need to reinvent themselves. Instead of planning broad, individual, successively scheduled campaigns, today multiple campaigns specifically aimed at micro-target groups continuously run in parallel. Instead of mass communication, consumers want personalization; instead of slogans, they want stories. Instead of broadcasting marketing content mainly in advertising slots and commercials regardless of whether it interests the audience, today the ultimate challenge is to deliver content that is interesting enough to be shared between friends (earned advertising).

And naturally smartphones are the medium of choice for most consumers. Marketing content needs to take into account the restrictions of mobile devices, such as the small screen, which limit presence, not just for banner advertising. Search engines show only a few hits on small screens, which means it’s imperative that ads appear at the top of the list. Conversely, mobile devices offer new opportunities such as geomarketing where the location of the consumer is identified via the smartphone, and local offers can then be sent to the screen to entice the potential customer to visit a nearby store.

The various digital communication channels present marketing with different challenges. By analyzing customer and usage data, marketers can address individual target groups specifically in these channels. In this new world of performance marketing, companies no longer buy advertising space on individual websites, but instead pay to reach target groups across a range of sites. The target group filtering is based on previous surfing habits. Tracking customers who viewed a certain product on store websites, particularly if they placed the product in the shopping cart but didn’t complete the purchase (retargeting), is particularly effective. They can then offer the same or a similar product again since the customer has already shown an interest. Search engine marketing is also aimed at very specific customer segments and purchases. Search engine optimization (SEO) optimizes the content and links of a company’s website to the algorithms used by Google so that the website appears right at the top of the hit list. Search engine advertising (SEA) purchases the top positions for paid advertising in the Google search results. Being positioned among the top hits is crucial to the success of both SEO and SEA. Between them, all search results that are not visible without scrolling receive less than 10 percent of all user clicks. SEA is paid per click, and that can get expensive. For example, in the United States, Google charges $2.90 per click for the top position in results returned for the search term “buy wine.” Companies that want their ad to be positioned at the top of the list for the keyword “mortgage” can expect to pay $15.30 for each click. And the search term “insurance” costs $31.10 per click for the top position. In other words, it’s easy for companies to calculate how high the conversion rate must be to make such an investment worthwhile. Marketing in social media is where it gets exciting, On Twitter, Facebook, Instagram, and the rest, it’s not about advertising slogans, but more about storytelling. This means a completely new way of thinking and organization for marketing departments; they need to think more like editors and less like advertising agencies. Content marketing is a key discipline in today’s digital marketing, and is explained in more detail next.Finding the Right Channel for Each Message

Content Is King

What story am I telling to whom? How, where, and when will I tell it? These are the questions that content marketing must answer. The last question is simple to answer: always. Essentially, there are four central success factors for digital content marketing:

- Continuity. Companies need to be always on, because today’s consumers expect continuous communication. This means producing more content in smaller units. For example, Burberry regularly publishes not only videos about its current collection on its YouTube channel, but also music videos with the greatest possible reach.

- Authenticity. Companies need their own authentic content that is appropriate to the respective platform. The messages will achieve their aim only if the users feel the content producer is competent in that field. For example, American Express gained significant reach with customers when it launched the OPEN Forum, which provides a platform for customers to connect with experts to help them solve many of their pressing business challenges, while at the same time connecting them with American Express’s brand messages. Content doesn’t necessarily need to be product-related, as Red Bull shows with its long-term involvement with sports and its resulting credibility in the field. The content should also be tailored to the medium: the communication style used on Snapchat, for example, is more spontaneous than the language used on narrative blogs, while the imagery on the virtual pinboard Pinterest is different from that found on Instagram, which mainly centers around snapshots.

- Relevance. Content marketing must understand precisely who the relevant customers are, which channels they use, and the kind of content they respond to. For millennials, explanatory videos are clearly important. We learned through research with McGarryBowen and Kraft Foods conducted by Google that 59 percent of 25- to 34-year-olds indicated they cook with either their smartphones or tablets handy. As a result, hardware chains like Home Depot, Lowe’s, and Ace Hardware have uploaded vast numbers of instructional videos to YouTube. In its online magazine Turn On and on its YouTube channel, electronics retailer Saturn explains the technology of its products. Supermarkets Safeway and Whole Foods have their own online cooking shows. The investment is worth it for retailers: In a survey of young adults, one-third revealed they had bought a product after watching the corresponding instructional video. A meta-analysis conducted by Google of 56 European case studies shows that in three-quarters of the observed cases the return on investment from YouTube campaigns was higher than that of TV commercials. In other industries, on the other hand, up-to-date content is what counts. This means producing more and more content in ever-shorter cycles, particularly during major events like the soccer World Cup. Adidas and Nike, for example, each put together their own editorial teams that virtually commentated live on matches on social media, while supplementing this with online content.

- Interactivity. Virtually all companies with an active online presence have at some point engaged directly with customers, who expect a fast response to a direct question. Take the example of United Airlines: because travel issues tend to generate a particularly high volume of queries on social media, the airline now promotes its 24-hour customer service on Twitter, Facebook, and LinkedIn to set itself apart from the competition.

How to Succeed in Content Marketing

To master all of these challenges, marketing needs to reorganize itself. It needs technology, organization, oversight, and control systems.

- Technology. A content management system can help the marketing team manage publishing processes and make them more efficient with the use of simple user interfaces. Media asset management (MAM) or data asset management (DAM) also stores images, videos, and text centrally, thus minimizing duplicate production. Analysis tools measure the impact of content, and in the event of negative responses, improvements can be made based on the data. Finally, targeting management systems and audience management systems help companies deliver the right content to the right target groups.

- Organization. Not only must processes be adapted to the new challenges, but the organization also needs to change. Classic marketing functions like strategy and creation are now supplemented with roles such as editor, writer, and content manager, whose skill profiles bridge editorial work and marketing expertise.

- Oversight. A coordinator oversees the right mix of paid content and owned and earned content. Owned content refers to all content that the company curates itself, be it on its own website or on its Instagram account. Earned content refers to the reach achieved when a post is shared, liked, reposted, and commented on by other users. Even though this unpaid reach may at first appear to be the company’s ultimate aim, it’s actually the mix that’s the most important. The transitions must be seamless for customers. Thus, successful earned content campaigns often lead to monetary gains.

- Control systems. Content marketing also requires continuous testing, measuring, and improvement. However, the success of content should not be measured just by its reach, but also by whether it goes viral—X percent of users share it with Y percent of their contacts. Customer responses can also be analyzed using special text analysis software and divided into positive, negative, and neutral contributions. This enables companies to identify successful content early and to initiate targeted seeding to broadening the content’s spread.

After Content Marketing Comes Programmatic Marketing

How will online marketing continue to develop? The trend toward precise, data-driven targeting of specific target groups will grow significantly with new advanced analytics approaches. Completely automated algorithms will increasingly be used to control the publication of digital marketing content. This is known as programmatic marketing. For example, when a user visits a website, the advertising space on that website is offered to advertising platforms in real time, and those spaces are allocated in a bidding process lasting just milliseconds—real-time bidding.

So what does this mean for the online marketing organization of a company? There must be a core team of in-house online marketing experts who understand these new technologies and their opportunities, and who ensure that the advertising budgets are deployed as efficiently as possible and continuously optimized. Too many companies currently outsource this work to external service providers. Expertise at the crossover between marketing and technology will become a new core competency for businesses that includes selecting the right marketing systems and tools. This poses a significant challenge to most of today’s marketing employees.

5.4 DIGITAL PRODUCT DEVELOPMENT AND OPEN INNOVATION: RETHINKING PRODUCT DEVELOPMENT

Michael Uhl and Belkis Vasquez-McCall on how digitization is changing development processes in all industries.

The Sonos speaker comes with an app that controls the digital radio, sends different songs to speakers in different rooms, and saves personal playlists for all members of the household. Today, all devices are connected to the Internet, transmitting data collected by their sensors. Cars have long since become four-wheeled computers. The products that brighten up our everyday lives and keep the economy going have changed. They’re becoming smarter as software’s share of the value added increases. For example, the car of today has more lines of programming code than was contained in Windows Vista, and it’s increasing all the time.

Software requires that development departments in many industries now rely on the methods of programmers. This is digital development, a structured route to new products and services. The developers combine digital and technological innovation in an agile, cross-departmental approach that drives projects to production stage with the end consumer in mind at all times. In this process, speed is more important than perfection. Try, fail, and learn are the core components of this method.

The digital innovation process (DIP) is determined by guiding principles, starting with modular structure. Developers begin with a focused project, and then transfer the results to neighboring areas. All innovations target the customer. In turn, customer feedback is then immediately reincorporated back into development. It’s agile and fast. The digital development process is efficient and never stops. The product is being constantly developed.

This product development philosophy was born in the digital economy and is now being adopted in the innovation processes of traditional analog products. Largely autonomous cross-departmental teams work on focused tasks and are committed to achieving specific stage targets without the interruptions of steering committees and management meetings—it’s the best of the start-up scene applied to business: independence, fun, and speed. By using a special interface or crowdsourcing platform, open innovation allows outsiders to contribute their ideas, and ideally bring them to market readiness using specially provided software tools. Open innovation doesn’t necessarily have to be limited to an entirely digital innovation process; it can also supplement a traditional development process. Surprisingly enough, the pioneer of open innovation wasn’t a digital company at all. It was Lego. Starting as early as 2005, the toymaker invited both adult and young enthusiasts to become part of its design team via the Legofactory.com website. This platform offered these would-be designers free software for designing their own Lego parts, and the best ideas were selected to be included in the range. Lego received both ideas and criticism via the Legofactory.com website. Particularly eager and technically proficient users discovered several weaknesses in the program. In 2012, Lego stopped the program because the individually designed and produced kits were too expensive for customers. Once again, the master of open innovation among the digital companies is Apple. The computer maker established application programming interfaces (APIs) for software engineers, giving them access to Xcode, a development environment in which apps can be written for the iPhone and iPad. After a testing process, the apps are then sold on Apple’s App Store. The developers enjoy the revenue, while Apple enjoys the commission and the value added to its hardware that allows its customers to do even more. Many other digital companies like Google and SAP are also using open innovation, and even telecom groups are tapping into the creativity of outsiders. Since an increasing number of products now incorporate software elements, the best example being smart TVs, this approach is interesting for a lot of industries. Companies that want to establish an open platform should bear in mind some basic rules. It’s important to define clear targets at the outset: what should the platform and its users accomplish? Then motivation needs to be considered: how will the codevelopers be rewarded? The third stage involves assessing the ideas and solutions, and the fourth stage focuses on organizing the network.Open Innovation and Open Development: Tapping into the World’s Creativity

Agile Product Development of Digital Products: Faster and Smarter to Market

At a time when customer tastes are changing ever more quickly, the traditional method of product development has proven increasingly unsuitable. It’s too slow, there’s too little feedback on the latest customer preferences, and there’s nowhere near enough flexibility. The product design is fixed long before the start of production, and in most cases can no longer be adapted dynamically to customer needs after market launch.

Agile product development overcomes these shortcomings as traditional companies look to the methods used by start-ups, which studiously examine trends and consumer preferences, and use their findings for product ideas. These are then tested and developed in a dynamic process, interacting with customers, even involving them in the early design phase. Prototypes are tested on the market, and the product’s final specifications remain flexible right up to product launch. Start-ups work by the philosophy that a product is never finished, but remains in constant development based on customer reactions.

One of the first to use this innovation process was Google: Even the company’s Gmail product was developed by a cross-functional team that comprised marketing, sales, and IT. First, the idea had to be approved by the Google Product Council, whose members include cofounders Larry Page and Sergey Brin, as well as CEO Sundar Pichai. Once teams have passed this test, they are allocated a budget and assume responsibility for their results. To successfully negotiate the path from idea to market launch, the developers must pass through three stage gates. Each of these gates to the next phase has clearly defined criteria, and each month, the team must report to CEO Pichai. Beyond this, no further coordination is needed in the company.

Agile product development requires an organization that is independent from the company. Samsung operates its Global Innovation Center as an independent unit with reporting lines running straight to the CEO. The money for projects comes from the various divisions, which specify strict stage targets for development. In turn, the divisions must create structures that enable fast responses and quick decision making. To recruit the best talent, the Global Innovation Center is based wherever there is a particularly high density of digital natives. Development centers are operated in New York, Silicon Valley, Tel Aviv, and Seoul.

To leverage external expertise and ideas, Samsung’s Global Innovation Center also participates in start-ups. A Samsung developer always switches to the freshly acquired company for up to one year to support the firm through to the proof of concept. However, the Global Innovation Center doesn’t work just with start-ups; it also works with other large businesses in the spirit of progress. For example, the South Koreans partnered with Intel to start the country’s National Internet of Things Strategy Dialogue.

A complete rethink of product development is needed. In the past, patents and internal expertise formed the primary source of innovation. This has now given way to the realization that markets are always more innovative than individual companies can ever be because market stimuli have become more important. Acting fast and trialing products in the right networks have become core competencies. Nonetheless, patents and intellectual property rights (IPR) will continue to be important in the future—they are the platform for innovation.

5.5 PRODUCT DESIGN: LEARNING FROM SOFTWARE DEVELOPMENT

Florian Weig on how the philosophy of software development is infecting every industry, and what engineers can learn from big data.

Why does the iPhone 7 Plus have two cameras? In 2016, buyers searched in vain for the reason. The hardware to take 3D photos was in place, but the software was missing. It’s typical Apple: the firm launches products that offer all the essential functions, but still leave their options open for additional functionality. Once the software for 3D images is ready, there’ll be an update, and the iPhone won’t just be able to shoot stunning 3D photos, but will also be ready for augmented reality or the overlay of additional computer-generated information or virtual objects. Exciting new features like these keep the device interesting for consumers even after long periods. The model is upgraded without changing the hardware.

Apple is entirely on trend with its understanding of new products and their development. Companies no longer bring finished, unchanging products to market; instead most regard product development as a dynamic process that continues throughout the product’s life cycle. This type of development centers around the internal software, and is becoming increasingly important in products of all industries. It’s called feature-based design. Digitization is fundamentally changing product development, from the product concept and development processes right through to data-driven decisions.

Rapid Improvements Rather Than Long Product Life Cycles

Design thinking is revolutionizing the way products are being developed, with a much stronger focus on customer needs, real-time incorporation of customer feedback in follow-up products, and products launched in ever shorter cycles.

The Customer Is King—and Codeveloper

By analyzing comments made on social media and online forums, and by analyzing sales data and information from sensors built into their products, engineers today have a much better idea of which product features and capabilities are really used and valued by customers. Our cars, for example, record how drivers use the electronic assistants, and send the information to the manufacturers as standard. This gives automakers a clearer idea of which features their customers value, which can then be used in later product development. Manufacturers of medical equipment also track every image produced by their devices and how each device is used.

Incorporating Data in Real Time

Never before has so much information about customer preferences and usage habits been available. The job of development teams is to reconcile this data continuously with the usage profiles of their products. Wherever there are shortfalls, including where they are caused by changing preferences or habits, adjustments are made.

Classic design consultancies like Veryday and Lunar have established a strong position in the development of digital products. As the ancestors of all modern designers put it during the Bauhaus era, “form follows function,” which is why Veryday and Lunar have added digital talent to their designer teams. It’s known as user experience (UX) design. The result is products that combine elegant and functional hardware with intuitive user interfaces and menu control. Since this competence has become so important, McKinsey recently acquired both firms.

Feature-Based Design: Gradual Improvement

Feature-based design was initially used by software companies and later adopted by related industries like telecommunications and the semiconductor industry. Now even domestic appliance manufacturers and automakers develop products based on individual features: Products start out with basic features, and are gradually improved. For example, most of today’s automakers use a specification called Autosar, which is used to add new features to their models by installing new software modules.

Feature-based design offers benefits for both manufacturers and buyers:

- Customers increasingly expect products to remain fresh and new in a world that’s developing faster all the time.

- Companies secure additional revenues with consistently high margins.

- Society and the environment benefit because the product platforms on which new features are added have longer life cycles, thus integrating better into the circular economy of tomorrow.

The new product development philosophy is also changing the customer relationships of sellers, who remain in constant contact with their buyers, and can earn additional revenues throughout the lifetime of their equipment. Electric carmaker Tesla is a shining example of this. Its cars come equipped with all the hardware necessary for semiautonomous driving, including sensors and control units. In 2014, the firm offered its customers the opportunity to upgrade their vehicles with an autopilot system. The software was sent to them for $3,000—a lucrative add-on with a very high margin.

Process Digitization—Acceleration and Virtualization

Tools are constantly being redeveloped to accelerate and virtualize processes. Core elements of agile development include feature road maps, virtualization and simulation, and smart systems for product life-cycle management (PLM) and product data management (PDM).

In the past, there was a development plan or road map leading to the finished product. Today, the product is only an indication of its current position on the development line. Engineers and programmers work according to a feature road map, developing individual modules that are then combined into a single product. However, each individual module is renewed in its own innovation cycle, and this can go very quickly in the case of software. In addition to the classic engineer who is responsible for one or more components, there is also a “feature lead,” who is responsible for a specific module such as a camera in a smartphone or a navigation system in a car. The feature lead plans several product generations in advance, and drives forward development.

And even moving away from software features, digitization has changed product design and development processes in other areas. Everything is becoming digital; processes are running faster, and becoming more transparent with big data analytics. Take machinery construction for example. ASML, the world leader in photolithography machines, uses lasers to map circuits onto wafers (the substrates for chips) and is able to upgrade its customers’ machines via software updates. These machines have built-in sensors, which continuously transmit data to ASML. After analyzing the data, the ASML engineers first develop ideas and then write programs to deliver improvements—for example, to ensure greater precision when aligning circuits with each other. These programs are then downloaded to the running machines via an app, increasing the performance of the machines without a panel being unscrewed.

And since everything today needs to be faster, developers use digital tools—such as in the design of new chips, where advanced simulations have now replaced hardware prototypes. Just four weeks after the start of a development project, engineers today have a virtual semiconductor on which they can fully test the functionality of the new chip, to which they can make changes without running into delays. This halves development time compared to the previous testing of prototypes. And once the chip emerges from the virtual space and is baked in silicon, it almost always works immediately, because virtual development enables more and better tests, and delivers considerably higher quality. In the past, developers seldom managed without building a second prototype, which could take another three to six months.

Honda offers another example of how digital tools are used. The Japanese carmaker is borrowing technology from Hollywood to learn more about crash behavior in the form of highly advanced graphics processors that the film studios use for their special effects. Honda combines its crash simulation software with 3D visualization programs to understand what happens to the vehicle structure in a crash. The system visualizes the energy wave that runs through the car after a collision. The warp patterns spread out like ripples on the water. The special effects software perfectly visualizes the destructive waves, enabling engineers to track the flow of forces and identify weak points in their design.

Virtual Training Is Faster and Cheaper

Today, it’s often much cheaper and faster to simulate a real machine as a virtual image to carry out tests or provide training.

For example, developers of the Lockheed F35 stealth fighter saved $100 million just by training their service personnel using a virtual jet rather than a real one: with 3D real-time visualization, or immersive engineering, the digital twin was almost exactly the same as its physical counterpart. Computer simulations are replacing many test flights. Physical air combat training in particular is extremely expensive and difficult, which is where augmented reality in the simulator comes into its own. The technology has helped Lockheed Martin to achieve more streamlined development processes, more efficient tests, and even better integration of production processes in its factory.

Simpler Development with PLM and PDM

Product life-cycle management (PLM) systems are based on product data management (PDM), and are used to integrate all the information generated during a product’s life, ideally across the entire value chain.

During the design phase, PLM prevents duplicate developments: Its database contains all the previous development work of engineers in a modular and parameterized system. An engineer about to start modeling a transmission system can access the preceding model, and if the dimensions are wrong, they can be extrapolated, which is just one of the benefits of the parameterized storage system.

Transparency Drives Efficiency

Advanced analytics and machine learning are playing an ever-greater role in development departments, generating a level of data transparency never seen before. As a result, processes can now achieve unprecedented quality and efficiency.

All the data concerning the development process is stored in a single database—from designs, schedules, e-mails, documentation, customer correspondence, and supplier information right through to personnel deployment planning. Today, this mass of big data can be analyzed for correlations with advanced analytics, and examined for potential success levers.

The pioneer of these applications is the British firm QuantumBlack, which has its roots in Formula One auto racing. Working with a Formula One team, the firm used its Nerve racing algorithm to analyze all the unstructured data accumulated over the course of a racing season. The aim was to increase the hit rate in the thousands of development projects conducted throughout the racing season to make the cars faster and more reliable. QuantumBlack linked project results and data with data about the structure of the development teams, identified correlations and causalities, and defined success levers based on the findings. Almost immediately, the ratio of new parts that led to actual improvements doubled, laying the foundations for the world title.

However, advanced analytics can also uncover elements that hold the productivity of developers back by shedding light on surprising relationships hidden in the sea of data. For example, McKinsey analyses for a client revealed that putting a development project on hold for just one week leads to an 8 percent loss in productivity. Also, the size of the team affects results. More than seven engineers on one team is too many, with each extra team member bringing a 7 percent productivity loss for the company in question. Another practice popular among global companies, where employees who are spread around the world work on the same task, also hinders progress: each additional time zone costs the firm on average around 5 percent in productivity. On the other hand, simply knowing the other people in the team has a positive effect. Teams that have worked together before are around 7 percent more productive than the average.

Artificial Intelligence Even Calculates Profitability in Advance

Using cost data, market data, and the assumed inverse demand functions, which are continuously compared against the current situation, machine learning systems with artificial intelligence can today forecast the likely profitability for each planned product variant, both per unit and across the entire life cycle. These data-driven predictions replace the previous extrapolation forecasts, and have thus led to a significantly higher hit rate.

Further Disruption to Be Expected

New technologies and new opportunities are appearing all the time, and developers in companies need to brace themselves for further disruption that will rock their job profiles. For example, will today’s 3D printers that produce prototypes in industries like machinery construction be used in full production? It would mean a completely new relationship between development and manufacture. And equally exciting is the question as to whether the trend toward customized production will lead to a co-creation model between customers and developers. We could see an entirely new product design process. Although still very limited, such a model is already being trialed with Nike iD where customers are able to customize their athletic shoes online from a selection of features.

The concept of co-creation has fired the imaginations of industry visionaries, who are already asking: Does a company even need to produce products anymore? Or will a viable business model emerge where the company simply offers a platform that provides co-creators with a basic design and the necessary customization tools? Once designed, the customer can then print out the product in the nearest 3D print shop. It may sound far-fetched, but it’s already happening. For example, in a number of online games, the players create and design their own characters—the company simply provides the platform and gamer network. Developers are barely needed—the customers do it.

5.6 FASTER, MORE FLEXIBLE, MORE EFFICIENT: SUPPLY CHAIN 4.0

Enno de Boer and Sumit Dutta on how digitization is changing every point in the supply chain.

Consignment warehouses have long since moved on from pickers running around racks with printed lists putting together shipments. Robots now bring entire racks to the workers or even put customers’ shopping baskets together themselves. Computers show workers equipped with smart glasses and headsets the correct routes through the warehouse. The workers then assemble their deliveries in the aisles, and scan the products with their smart glasses to avoid errors. Routes are calculated with sophisticated algorithms to optimize journey times. Everything is wonderfully digital and efficient, unless a new algorithm is needed because the old one had weaknesses. In the conventional model, that can take a long time. The requirement has to be specified; a budget has to be applied for; an order is sent to a trusted software company, which takes away development work from employees who can’t program; a prototype is tested; and sooner or later, maybe six months or so down the line, the new algorithm is installed.

With digitization, it’s not just the logistics chain that runs faster than before; offices are also setting a new pace. When a leading European e-commerce company decided to make its picking processes more efficient, the team worked a whole day to determine whether the algorithm could be improved. After some quick research, they found a routing algorithm for making pickers’ routes through warehouses more efficient. The team then optimized this algorithm to the company’s needs, and the chief information officer personally implemented it throughout the system. This was possible because they had programmed the warehouse management system, which is ultimately the heart of warehouse operations itself, rather than installing an inflexible standard product. Comparison tests on the performance of the new algorithm revealed that pickers’ routes were reduced by 10 to 15 percent. After just six working days, the solution was so advanced it could be installed in all of the other warehouses.

This example is a perfect illustration of the management approach needed for the digital age. Speed and customer-centric thinking count. Fast, data-driven decisions are made; development work factors in fast failure; there is an eagerness to experiment, as well as transparency and team spirit.

There’s plenty of opportunity for failure right now because logistics currently faces massive upheaval. Big data and advanced analytics, the ability to search huge unstructured data volumes for correlations and causalities, together with robot technology and the Internet of Things, are revolutionizing the management of the supply chain. Sensors are everywhere, and everything is connected. Each step is automated, every aspect is analyzed, and logistics companies and their customers are the winners.

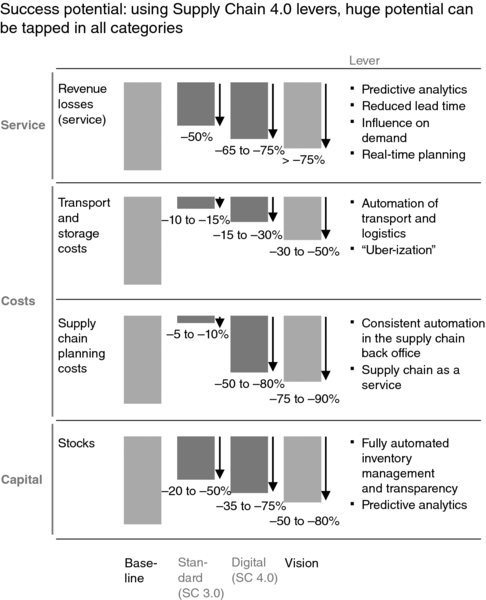

Following on from Industry 4.0, Supply Chain 4.0, as it has become known, saves a lot of money. According to a McKinsey study conducted in 2016, Supply Chain 4.0 reduces transportation and warehousing costs by 15 to 30 percent, and revenue losses resulting from nondelivery by as much as 65 to 75 percent. With better scheduling, retailers can reduce stock on hand by 35 to 75 percent, depending on the industry, and planning and order processing costs by 50 to 80 percent. Customers in turn benefit from more accurate delivery times and more flexible logistics companies, which can tailor the place and time of deliveries to suit consumer preferences.

Seven Innovations That Revolutionize the Supply Chain

In 2016, the Supply Chain 4.0 Innovations Survey examined which currently foreseeable innovations would change the supply chain in the coming years. Of the 53 innovations identified, seven have the potential to disrupt the current business model.

Better planning with big data and advanced analytics supported by machine learning systems that have artificial intelligence will optimize every step in the supply chain. In addition to internal data, planners of delivery routes, warehouse stocks, and requirements also use external information ranging from traffic reports to current consumer demand. Predictive analytics can model demand trends, and already some companies are using such a cloud-based analysis model from the provider Blue Yonder. UPS, for example, used on-truck telematics and advanced algorithms to optimize routes and reduce engine idle time, saving the company over 39 million gallons of fuel and avoiding 364 million miles of unnecessary driving.1

Semiautonomous and fully autonomous trucks are one of the most important innovations. In a recent study, McKinsey found autonomous trucks result in approximately 10 to 15 percent lowered fuel consumption by optimized driving, and 15 percent reduction in carbon footprint due to optimized driving. Mining group Rio Tinto already uses driverless haul trucks in its mining operations. Experts, however, don’t expect driverless trucks to appear on public roads within the next five years.

With 3D printers, the rules will also soon change when it comes to warehousing and product availability, particularly for slow-moving items and spare parts. In 2015, Amazon experimented with installing 3D printers in its delivery vans, and even patented the idea. Orders are printed on demand in the delivery van itself, with extensive customization possibilities and unprecedented delivery times. Bosch has invested a lot of money to test 3D printing of metals and ceramics, which it hopes in the medium term will allow it to print spare parts for machines on-site. Airbus and General Electric are also already using 3D printers to produce individual aircraft and turbine parts. Yet despite the highly promising applications, a McKinsey study estimates that it will still be another 10 to 15 years before 3D printing becomes the norm.

Logistics Platforms and Shared Planning

Cloud logistics platforms offer significant benefits such as dramatically increasing truck fleet utilization. Cloud-based logistics platforms connect shippers and transport service providers, optimizing utilization and mileage driven. An unlimited number of companies, both customers and freight forwarders, can register via a simple app and connect.

Shared planning in the cloud between manufacturers and their suppliers also means more efficient collaboration. Cloud-based logistics also reduces the bullwhip effect where supplier purchase orders always fluctuate more strongly than consumer demand, leading to excess overstock, overcapacity, and higher costs. With cross-company shared planning, changes in demand are reported in real time, which means companies can respond accordingly and prevent overstock and overreactions. Companies in the field of consumer electronics are already very closely integrated with their suppliers, and use planning solutions such as E2open to deliver seamless planning.

Information platforms on which companies share nonconfidential and nonanonymized data provide the fuel for advanced analytics, which enables more precise predictions of demand and optimized logistics routes. Information shared on these platforms includes details about disruptions in supply chains, hacking attacks on systems, traffic updates, and much more. The challenge is to expand such information systems and then establish a reliable connection to the IT infrastructures of customers. Experts believe that these information platforms will become widespread in just a few years.

First Steps toward Supply Chain 4.0

The journey toward the supply chain of the future must start with some critical stocktaking. Management must review the entire supply chain to assess its suitability for the switch to digitization. Data flows, analysis capabilities, hardware and software, talent, and processes must all be analyzed at every point in the supply chain, and assessed on a 1 to 5 scale where 1 denotes predominantly paper data and 5 denotes digital excellence. The findings will then form the foundations for the digitization process. Initially, very specific, isolated projects are recommended—for example, projects focusing on achieving greater efficiency in pick processes or improved forecasting. This type of approach will help yield the agility and pace of start-ups.

The efforts to digitize the supply chain are worth it, but will not deliver cost reductions on their own, but rather a range of solid improvements.

- Faster pace: Delivery times for fast-moving items will be reduced to a few hours thanks to more precise estimates and planning based on the analysis of large data volumes. Soon, logistics companies will switch to predictive shipping, where products are sent for dispatch even before the order has been received from the customer. Amazon has already patented such a method that calculates freight and routes. Once an order is received, the system searches for the product on a delivery van in the region, and the driver is promptly directed to the delivery address.

- More flexibility: Planning cycles and periods in which the company is unable to respond are minimized by real-time planning methods. Instead, planning becomes a revolving process in which dynamic adjustments are possible. For example, if a product is already on its way to a customer, the customer can still have it redirected to a destination that’s more convenient. Similar to developments such as software as a service, we will see supply chain as a service where service providers assume responsibility for the company’s entire supply chain. Companies pay the service provider according to the services used, which means they don’t have to invest in their own resources or capabilities. Another trend that will deliver greater flexibility is the “Uber-ization” of transportation. Crowdsourcing enables people with free capacity, such as Uber drivers who currently have no customers, to deliver packages. All of these solutions make delivery networks far more agile.

- Greater depth of field: Customers want increasingly customized products, and mass production of tailored products is now expected. This requires micro-segmentation of customer groups, with companies having to readjust to much smaller target groups while offering a broader palette. In terms of the supply chain, customers will expect to be able to choose from a wide offering of logistics solutions and select the one that precisely fits their needs.

- More precision: The next generation of key performance indicator (KPI) systems will deliver real-time transparency across the entire supply chain. These will range from management KPIs such as the service levels to operational data such as the precise position of the delivery vans at the current time. We will see machine learning systems that automatically identify risks and immediately modify parameters—for example, calculating new truck routes. An automatic control center will independently react to a wide range of problems and deviations without any human interventions with continuous system learning.

- Greater efficiency: The efficiency of supply chains is increasing sharply because both physical tasks and the entire planning process are going digital. In the warehouse, robots are taking over all the work; autonomous trucks and delivery vans will assume driving responsibilities on longer routes, while delivery bots and drones take over the last mile. To deliver greater utilization, supply chain organizations will pool capacities and form a network whose organization must in turn meet the needs of all its members.

5.7 DIGITAL LEAN: THE DIGITIZATION OF PRODUCTION

Varun Marya and Gianluca Camplone on the five fundamentals of digital production.

Let’s look ahead to the factory of tomorrow and beyond: Drones with 360-degree cameras fly through the warehouse area capturing images that are translated into 3D drawings to optimize material flow and work flows. Autonomous transport vehicles trundle across the factory floor and through the production halls while, alongside human workers at the assembly lines, robots assume the arduous tasks. All the machines are in working order; with predictive maintenance, there is almost no downtime, as data are automatically captured and sent to the cloud. The 3D printers produce prototypes and spare parts, and apply customizations to the finished products at the end of assembly lines. There’s no refuse or scrap—the factory of tomorrow doesn’t produce waste. Data are exchanged throughout the value chain from the raw material right through to the product in use. This is digital lean, the evolution of lean manufacturing, whose principles have conquered the world of manufacturing since its Japanese beginnings in the 1980s.

Digital Lean: The Same Aims as Lean Production

Digitization is giving new impetus to the concept of the continuous improvement process, one of the cornerstones of lean production. This is because digital technology is strengthening the competitiveness of companies in the three core areas: it helps to control costs, eliminate waste, and optimize production. Huge productivity increases are possible.

Today, productivity and quality studies can be simulated on computers, which dramatically reduces development times. Stock inventory warehouses are redundant because demand forecasting is so precise that companies are virtually able to manufacture to order. With predictive maintenance, machine availability will approach 100 percent rather the current 40 to 80 percent. Optimized processes and smart energy consumption will enable energy savings of up to 20 percent compared to today. The automated transport systems in the factory will work far more cost-effectively and efficiently because they are no longer restricted by rail systems. Robots in Factory 4.0 are cheaper to program, and constantly learn with artificial intelligence. Employees will be more skilled, with continuous training and development. Considerable savings beckon in the entire production value chain of tomorrow.

The philosophy of digital lean doesn’t end at the factory gates. With the Internet, companies can now largely integrate their own processes with those of suppliers and customers. For example, automakers can analyze information about the activities of their suppliers together with up-to-date consumption data of customers from social media analyses to predict future demand patterns. As a result, the auto industry is able to make extremely accurate predictions regarding the extent to which extra features will be ordered with sales of new cars, enabling more precise production planning. Other companies use the Internet to manage their branched production sites. A large energy utility, for example, monitors all of its drilling rigs in the Gulf of Mexico from a central control room.

A by-product of digital lean even allows a restructuring of the global distribution of labor. Because manufacturing is far more flexible and automated than before, hardly any individual work steps will be outsourced in future, and even the offshoring of full production to low-wage economies will be virtually eliminated. “Local for local” is the new philosophy: factories manufacture locally for local demand. This will be a blow to developing countries because the labor cost advantage will no longer be as relevant. However, one of the benefits for industrial nations is that some of the workplaces lost as a result of advances in productivity will be transferred to the new manufacturing.

The productivity gain in digital production is brought by the widespread use of data analyses, sensors, robots, and other new technologies such as 3D printing, all driven by the large-scale use of computer capacities and servers. And yet the aims are the same as lean production in the past. It’s about increasing productivity and reducing waste, from machine downtimes to nonproductive worker activities. And just as before, the transformation primarily centers around three central dimensions: the technical system (processes and tools), the management system (organization and performance management), and the human resources (HR) system (skills and attitudes of employees). Digitization also brings a fourth pillar into play: data, IT, and networking as value drivers.

Five Central Themes for the Transformation

Five central themes have emerged from previous experiences of digital transformation processes.

- Digital lean significantly increases productivity. With persistent cost pressures, most companies try to increase productivity by two to four percentage points each year. As numerous studies have shown, digitization has the potential to make production 15 to 20 percent more efficient. This requires several individual solutions working together across the entire value chain. For example, predictive maintenance and remote monitoring of machines can reduce downtimes by 30 to 50 percent, significantly increasing equipment utilization. Optimizing labor efficiency also has great potential. Digital performance management and large-scale use of ever more powerful robots that can replace human labor not just in production, but also in logistics, can increase working productivity by 40 to 50 percent. Advanced analytics of extensive volumes of machine data in real time can identify inefficient processes and quality problems. Because the entire process of sales forecasting is becoming much more accurate with big data, companies can dramatically reduce warehouse stocks while also improving delivery capacity.

- Digital lean isn’t about IT, but about business. Although the IT department provides the tools for digital production, it isn’t responsible for how it’s deployed. On no account must the digital transformation process begin with the question of how the new technology can be integrated into the old IT system. Digital lean starts at a much more fundamental level. It’s about how the business should look in the future, and what that means for the value chain and business model. For example, a manufacturer of sports apparel wants to make sports shoe production much more customized. This changes the value chain dramatically. To leverage the cost benefits of production in low-wage economies, companies today accept long shipping times for container shipments to Europe and the United States, as well as the equally low flexibility. Soon, the wholesale use of production robots not only will make high-wage economies competitive, but it will also reduce the time to market from product design to start of sales, it will reduce freight costs, and, thanks to the greater flexibility of automated production, it will even be able to deliver cost-effective product personalization.

- Digital lean is a job for top management and cannot be delegated. To date, only a few companies have a structured plan for addressing the topic of Industry 4.0. According to a recent study by McKinsey, only 15 percent have formulated an actual strategy. Around 20 percent have defined responsibilities in their organization, typically as a staff function without the authority to make direct decisions. Where line functions do have responsibility, these are usually too low in the hierarchy, and therefore also lacking the strength to combat inertia. Once again, the methods used to introduce lean production at the end of the last century can help; if the transformation is to deliver value quickly, the company management must take control.

- Digital lean requires a holistic transformation approach. Just like the transformation to lean production, the digitization of the factory at scale tackles all components of the value chain and prepares them for digital. Many of these individual initiatives are coordinated centrally and must include a program for equipping employees with the necessary skills, and a plan focusing on how to establish digitization throughout the company. This is Digital@Scale. Isolated projects that are not linked to other projects or anchored in the foundations of the transformation are of little help, and often fail in their early phases.